Difference between Conventional and Parallel plate gravity separators?

Earth contains many resources. One of the most important elements of life is water. However, only about 3% of the water on earth is freshwater and can be used for human and animal consumption. For this reason, it is important to find a way to treat and decontaminate contaminated water. One of the best ways to do this is to use a water and oil separation system.

As the name implies, these water treatment products are used to remove oil and other pollutants from wastewater in commercial or industrial land, or where oil can pollute the environment.

The following are some of the most common types of oil-water separator systems:

1: Traditional Gravity Separator (API)

Traditional gravity separators use gravity to separate oil and other contaminants from wastewater. This works because oil is lighter than water. Therefore, when oil-water separator is placed, the oil rises up, solids and deposits sink down, and the water stays in the centre. The oil is then scooped from the top and discarded, while the wastewater is free to flow through the outlet on the side of the tank and can be further treated or released to the environment. The solid and sediment layers are scraped from the bottom into the slurry pump for disposal.

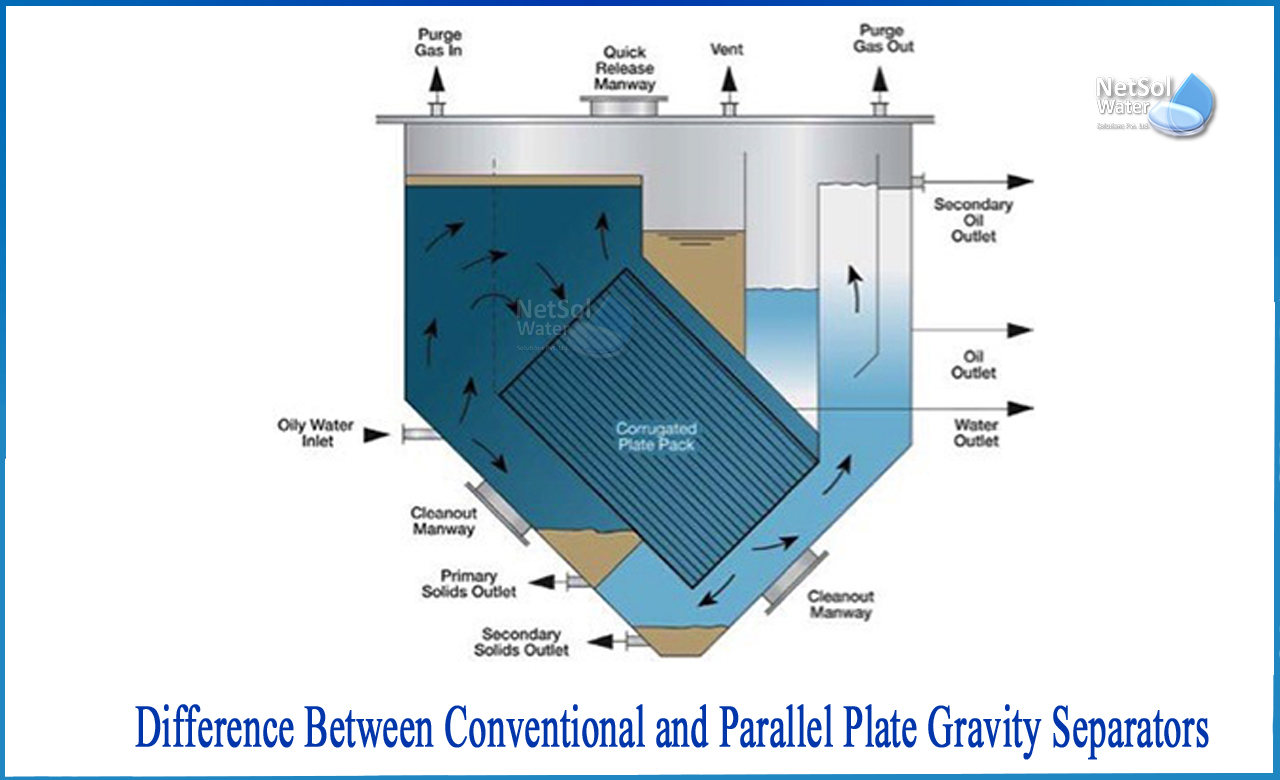

2: Parallel plate gravity separator

In this type of water-oil separation system, corrugated sheets of lipophilic material are placed parallel to each other in tanks about 612 mm apart. Water and oil then flow through the tank between these plates. The oil in the wastewater is attracted and adheres to the plate.

As more and more oil droplets accumulate, they form larger droplets that eventually rise to the surface where they are collected and dumped in a waste oil tank. Currently, oil-free water continues to flow through the tank to a clean water outlet, where it can be discharged for other uses.

Other types of separators:

3: Liquid Cyclone Water Oil Separator System

The Liquid Cyclone Water-Oil Separator system uses an active vortex that is generated when oil water is injected diagonally into the tank. Centrifugal force accelerates, creating a cyclone or spiral shape. Because water is denser than oil, it can be pushed to the outer edge and fall towards the outlet, leading to further treatment and the environment.

Light oil is pushed to the centre and pushed from the top into the waste oil tank. This type of separator is suitable for very efficient oil removal from wastewater like in factories and heavily polluted waters.

4: Froth flotation separator

The final water-oil separation system, commonly referred to as DAF (Dissolved Air Flotation), uses dissolved air to increase the rate of oil rise.

At the separator, oily water mixes with wastewater saturated with dissolved air, creating small bubbles. Oil in the wastewater attaches to these bubbles and is carried to the surface of the separator, where oil, sludge and solids are scooped out and retained in a separate tank. Solids and deposits that are too heavy to rise sink to the bottom, where they are collected in drains.

The DAF drainage is then routed through the outlet and can be reused or further filtered. Each separates oil and water in a slightly different process, making it superior to other processes depending on the intended use in a particular company or industry. Factories, restaurants, trading companies, and shipping departments choose to use these water treatment systems in conjunction with their operations to make them more efficient, healthier, and more environment friendly.

Conclusion

There are different types of oil-water separators, each have their own advantages and disadvantages. We at Netsol have more than ten years of experience in the industry. We can provide customized products for water and wastewater treatment across India.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.