Designing an ETP for Paper and Pulp Industry: A Step-by-Step Guide

Effluent treatment plants are crucial in the paper and pulp industry to ensure the safe discharge of industrial wastewater into the environment. The treatment of effluents from paper and pulp industries is necessary to avoid environmental pollution and harm to human health. The process of designing an effluent treatment plant for a paper and pulp industry involves several steps.

Here we aim to provide an overview of these steps and the essential components of an effluent treatment plant for the paper and pulp industry.

Design Process:

The design process of an effluent treatment plant for the paper and pulp industry includes several steps. These steps include:

· Preliminary Assessment: The first step in designing an effluent treatment plant is to conduct a preliminary assessment of the wastewater characteristics, volume, and quality. This step helps in identifying the contaminants present in the wastewater and their concentration.

· Design Basis: Once the preliminary assessment is complete, the next step is to determine the design basis of the effluent treatment plant. This step involves selecting the treatment processes, sizing the equipment, and determining the hydraulic and organic loadings.

· Process Design: The process design step involves selecting the appropriate treatment processes and equipment for the effluent treatment plant. The selection of the treatment processes depends on the contaminants present in the wastewater and their concentration.

· Detailed Engineering: The detailed engineering step involves preparing the detailed engineering drawings, specifications, and procurement documents. This step is critical as it ensures that all the equipment and processes are properly sized, and the plant can function effectively.

Type of Effluent:

The ETP for a paper and pulp industry may have to handle high levels of organic matter, color and lignin in the effluent.

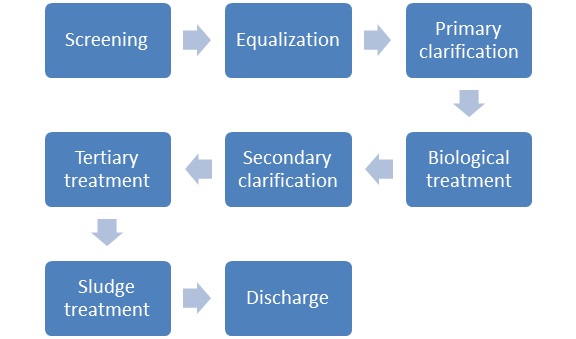

Process Flow Diagram:

The process flow diagram of an effluent treatment plant for the paper and pulp industry typically includes the following treatment processes:

Working:

· Screening: This step removes large objects and solids from the effluent using screens or filters.

· Equalization: This step balances the flow rate, pH, temperature, and concentration of the effluent using a storage tank or a basin.

· Primary clarification: This step separates the primary sludge from the effluent using gravity or flotation methods.

· Biological treatment: This step degrades the organic matter and nutrients in the effluent using aerobic or anaerobic microorganisms in reactors or ponds.

· Secondary clarification: This step separates the secondary sludge from the effluent using gravity or flotation methods.

· Tertiary treatment: This step removes residual pollutants such as color, turbidity, metals, or pathogens from the effluent using advanced methods such as chemical coagulation, filtration, adsorption, or disinfection.

· Sludge treatment: This step handles the sludge generated from the previous steps using dewatering, drying, stabilization, or disposal methods.

· Discharge: Once the wastewater has been treated, it is discharged into the environment. The discharged water must meet the regulatory requirements for environmental discharge.

Chemicals Used:

Some of the chemicals used in the effluent treatment plant for the paper and pulp industry include:

· Alum (Aluminum Sulfate): Used for coagulation and flocculation.

· Lime (Calcium Hydroxide): Used to adjust the pH of the wastewater.

· Sodium Hypochlorite: Used for disinfection.

Summary:

Effluent treatment plants are critical in the paper and pulp industry to ensure the safe discharge of industrial wastewater into the environment. The treatment processes involved in an effluent treatment plant for the paper and pulp industry typically include screening, equalization, chemical treatment, coagulation and flocculation, sedimentation, filtration, and disinfection. The design process of an effluent treatment plant for the paper and pulp industry includes several steps, including the preliminary assessment, design basis, process design, and detailed engineering.

The working function of an effluent treatment plant for the paper and pulp industry involves several steps, including wastewater collection, screening, equalization, chemical treatment, coagulation and flocculation, sedimentation, filtration, disinfection, and discharge. Overall, designing an effluent treatment plant for the paper and pulp industry requires careful planning, analysis, and design to ensure the safe discharge of industrial wastewater into the environment.

Leading manufacturer of sewage treatment plants in India.

Netsol Water is the leading manufacturer, supplier, and exporter of a quality selection of water treatment, and wastewater treatment products in India, by using advanced sewage treatment methods.

RO plants, water softeners, ETPs, STPs, DM plants, AMC, O&M, Ultra filtration, UV, Ozonation, ZLD plants, Anoxic tanks, and other goods and services are available from us. We also provide services to businesses in sectors including automotive, pharmaceutical, textile, pulp & paper, beverages, refineries, schools, hospitals, office buildings, and hotels, among others.

Call us at +91 9650608473 or email at enquiry@netsolwater.com for further information.