What are Sequencing Batch Reactors?

Sequencing batch reactors (SBR), also known as sequential batch reactors, are industrial wastewater treatment tanks. These reactors handle wastewater in batches, such as sewage or waste from anaerobic digesters or mechanical biological treatment plants.

It is a wastewater treatment technology that uses a fill-and-draw activated sludge technique. In this system, wastewater is pumped into a single "batch" reactor, where it is treated to eliminate contaminants before being released. Equalization, aeration, and clarifying processes take place in a single batch reactor. Two or more batch reactors are employed in a specified sequence of operations to improve the system's performance.

What are the Design procedure for SBR Systems?

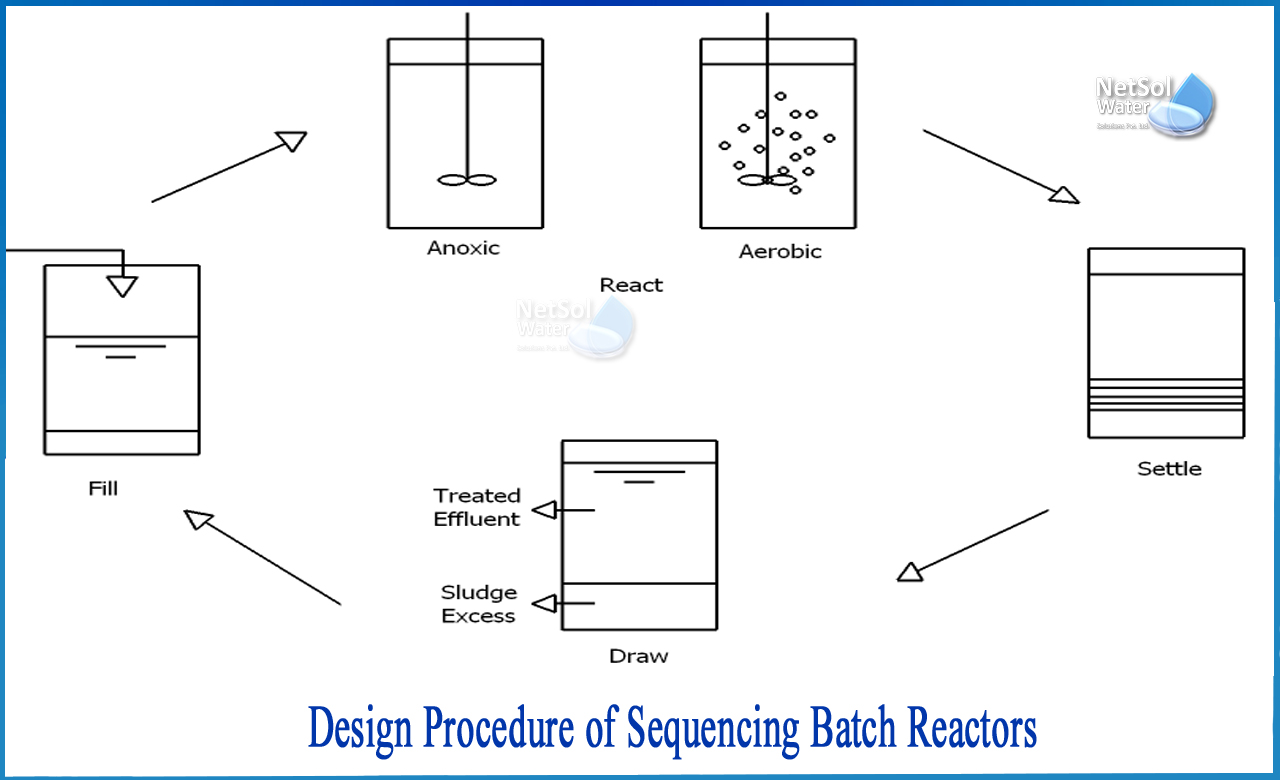

Fill, react, settle, decant, and idle are the five steps of the procedure.

1: Fill

During the Fill process, influent wastewater is injected to the reactor.

The Fill phase is divided into three types, which can be employed in any order depending on the operational strategy:

Static fill: During static fill, influent wastewater is added to the biomass already present in the SBR. It is used during the initial start-up phase of a facility and during low flow periods to save power. There will be a high substrate (food) concentration when mixing occurs in a static fill situation since there will be no mixing or aeration.Furthermore, organisms that develop internal storage products during high substrate conditions, which is required for biological phosphorus elimination, benefit from static fill circumstances.

Mixed fill: This is defined as a mixture of influent organics and biomass that triggers biological processes. The mixing motion ensures that the influent wastewater and biomass are mixed uniformly. During mixed fill, microorganisms breakdown the organics biologically and utilize leftover oxygen or other electron acceptors such as nitrate nitrogen to do so.During the mixed-fill phase, anaerobic conditions can also be created. Phosphorus is released from biomass in anaerobic circumstances.

Aerated fill: Aerated Fill is distinguished by aerating the reactor's contents to kick-start the aerobic processes that were started in the React stage. Aerated Fill can cut down on the amount of aeration time needed in the React stage. To minimize organics and accomplish nitrification, no changes to the aerated-fill cycle are required. However, in order to achieve denitrification, the oxygen must be turned off in order to induce anoxic conditions.

2: React

This phase allows for further reduction or polishing of wastewater parameters. No wastewater enters the basin during this period, and the mechanical mixing and aeration devices are turned on. The rate of organic elimination rises considerably since there are no increased volume or organic loadings. The react phase is when the majority of the carbonaceous BOD is removed.

3: Settle

Activated sludge is allowed to settle under quiescent conditions throughout this phase, with no flow into the basin and no aeration or mixing. The activated sludge forms a distinct interface with the clear supernatant as a flocculent mass settles. The sludge blanket is the term for the sludge mass. This is an important element of the cycle because if the solids do not settle quickly enough, some sludge will be pulled off during the decant phase, lowering effluent quality. In SBR, unlike a normal activated sludge system, there are no influent or effluent currents that obstruct the settling process.

4: Decant or Draw

A decanter is used to extract the clear supernatant effluent during this phase. A signal is transmitted to the decanter to activate the opening of an effluent-discharge valve after the settle phase is complete.

5: Idle

Between the decant and fill processes, there is an idle period. Depending on the influent flow rate and the operation strategy, the time varies. A little quantity of activated sludge from the bottom of the SBR basin is pumped out during this phase, a process known as wasting. The length of the idle phase is determined by the influent flowrate as well as the operating strategy. If varied idle durations are employed, equalization is achieved during this stage.

What can we offer?

Netsol Water is one of India's major water and wastewater management company, specialized in the design, manufacture, and delivery of custom-made treatment systems, industrial machinery, and luxury amenities for the water industry. We can customize Sequencing Batch Reactors (SBRs) that will cater to all your needs and at the same time effectively treat different types of wastewater.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.