What is the designing Criteria of WWT in Leather Industry?

Environmental imperatives, such as the requirement to satisfy specified discharge limits, decreased treatment costs, or comply with workplace safety and health regulations, typically drive the adoption of cleaner technology. Lowering water consumption, improving chemical absorption, improving solid waste quality/reusability, and lowering the amount of particular contaminants like heavy metals and electrolytes are all common primary goals.

Load of pollution in Leather industries

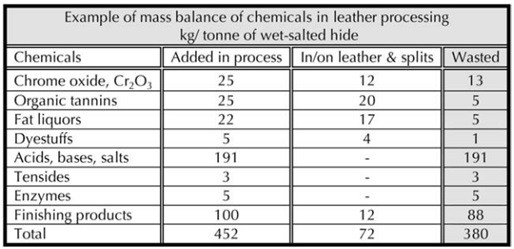

It's no surprise that statistics for pollutant load in the literature vary a lot because to differences in raw materials, processes, chemicals, water consumption, and so on. They should be read with caution.

The tables below can give you a rough estimate, with one tonne of wet-salted hides as a standard.

Before moving on to treatment procedures, keep in mind the following!

• The design of an ETP is always adapted to the requirements of a given site; hence, no two ETP are same.

• Pollutants in wastewater cannot be removed; they can only be transformed into something that is more ecologically friendly or simpler to dispose of (sludge).

• Surprisingly, the obvious is sometimes overlooked: the same quantity of pollutants at reduced water consumption results in a smaller hydraulic load (volume) but a greater concentration, which is difficult to treat.

• In order to lower the total cost of treatment, a tanner must grasp the relationship between the leather technology used and wastewater treatment.

Treatment of Wastewater in Leather Industry

Wastewater treatment is a multi-stage procedure that purifies wastewater before it is discharged into a body of natural water, applied to land, or reused. Because each receiving body of water can only take a given amount ofcontaminants without degrading, the objective is to decrease or eliminate organic matter, sediments, nutrients, Cr, and other pollutants. As a result, each effluent treatment plant must comply to discharge criteria, which are often established by the appropriate environmental authority as permitted levels of pollutants represented as BOD-5, COD, suspended solids (SS), Cr, total dissolved solids (TDS), and others for practical reasons.

We refer to the following treatment stages in a rather arbitrary and inconsistent manner:

![]() Preliminary treatment

Preliminary treatment

Primary treatment

Secondary treatment

Tertiary treatment

A: Preliminary treatment: Individual tanneries must often have pre-treatment units built in common effluent treatment facilities (CETPs) servicing tannery clusters, which are widespread in poor nations. Before the effluent is released into the collecting network, they remove big particles, sand/grit, and grease, as well as drastically lower the level of chrome and sulphides.

Basic steps include:

1: Screening (bar, self-cleaning);

2: Pumping/lifting;

3: Fine screening;

4: Equalization and sulphide oxidation;

5: Chemical treatment (coagulation, flocculation);

6: Settling;

7: Sludge dewatering

B: Treatment using physical and chemical agents (primary): Sedimentation is used to remove settleable organic and inorganic particles, whereas skimming is used to remove substances that will float (scum). During initial treatment, 25-50 percent of the biochemical oxygen demand (BOD-5), 50-70 percent of total suspended solids (TSS), and 65 percent of oil and grease are eliminated. Primary effluent and sludge are the effluent and sludge produced by primary sedimentation.

C: Biological treatment or secondary treatment: Secondary treatment usually comes after primary treatment, with the purpose of removing biodegradable dissolved and colloidal organic waste utilizing aerobic biological treatment techniques.

Aerobic biological treatment involves aerobic microorganisms (mostly bacteria) metabolizing the organic content in the wastewater and creating additional microorganisms and inorganic end products in the presence of oxygen (principally CO2, NH3, and H2O). For secondary treatment, a variety of aerobic biological processes are utilized, with the distinctions essentially relating to how oxygen is delivered to microorganisms and the pace at which organisms digest organic materials.

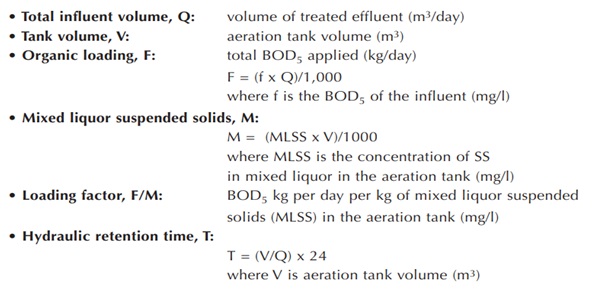

The main operational parameters important to understanding the process are-

D: Tertiary treatment: Tertiary or advanced wastewater treatment is used to minimize residual COD loads and/or when earlier treatment stages have failed to eliminate certain wastewater elements.

The quality of the final effluent in certain situations does not satisfy the authorized discharge limitations, despite thorough physical-chemical and biological treatment in a well-designed ETP. Recalcitrant COD, or chemicals that the microorganisms in the floc are unable to breakdown, is the most common reason.

Additional, typically more difficult and expensive treatments, such as mineralization of organic compounds by oxidation with H2O2 in the presence of ferrous sulphate, are required in such circumstances (Fenton process and its derivatives). Ozonation is occasionally used to remove some of the leftover COD, rather than to kill potentially dangerous microorganisms. Now-a-days, reverse osmosis is also used to achieve much better quality of water.

What can we offer?

Netsol Water is one of India's major water and wastewater management company, specialized in the design, manufacture, and delivery of custom-made treatment systems, industrial machinery, and luxury amenities for the water industry. We provide customized services addressing customer needs promptly and effectively using industry-certified standards.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.