What is Crystallizers in Zero liquid discharge systems?

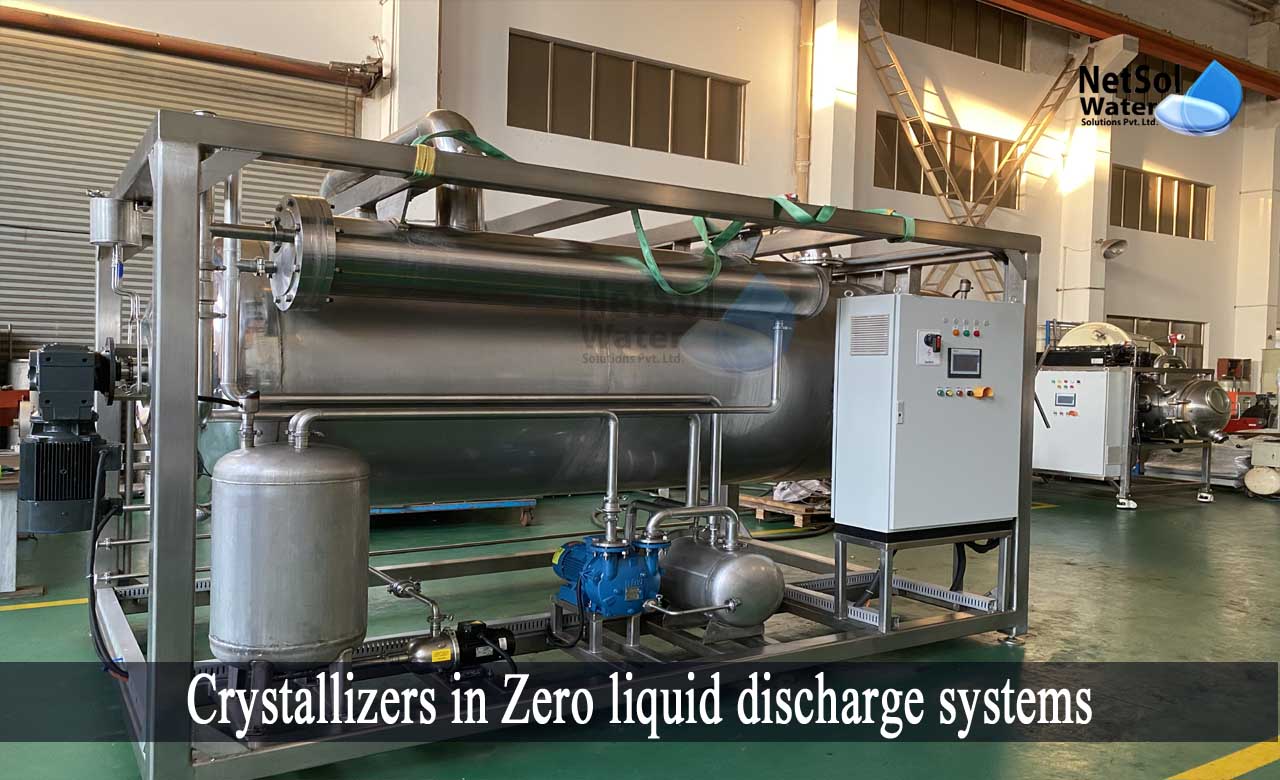

Crystallizers are the most effective technique for establishing ZLDs (Zero Liquid Discharge Systems). It separates wastewater into two streams, one of which contains solid waste with usable resources, and the other of which contains high-quality, recyclable water.

The vacuum crystallizer's role is to evaporate all solvents, leaving a highly concentrated, pasty, gelatinous, or glossy result. This technology in the zero discharge system is extremely efficient, and has a very low management cost.

What is Crystallization?

Crystallization is a physical transformation process. The creation of solids from a liquid or gaseous phase is known as crystallization. This method involves extracting soluble crystals from a hot saturated solution, and separating the soluble solid from the solvent.

Crystallizers are used to concentrate feed into solid crystals and purify water. It is an increasingly tougher procedure, for forming crystallite sizes from a liquid solution. Crystallizers can totally eliminate liquid wastes, resulting in no liquid discharge (ZLD).

Crystallization Process Types

The two stages of crystallization are primary crystallization and secondary crystallization.

Primary step refers to the creation of new crystals, and the fundamental step that culminates in crystal mass creation is secondary step.

There are two types of crystallization processes

· Evaporative crystallization.

· Cooling crystallization.

A careful assessment of the application's needs is required before selecting crystallizers. For example, a salt crystallizer transforms brine into solid salt crystals and clean water. A continuous cooling crystallizer is used to crystallize other sorts of salts.

Effluent Recycling through Crystallizers

Crystallization is known as the separation method. Crystals are formed as liquids or gases during the separation process. The crystallization process yields exceedingly pure solid crystals. As a result, the crystallization technique may also be employed for industrial cleaning.

The most critical step in the creation of solid crystals in a liquid solution is concentration and cooling, until the solute concentration is higher than dissolved at that temperature, and the solute forms pure crystals.

Supersaturation Techniques

The solution must be supersaturated for the crystallization process to occur. The process of supersaturation for crystallization is completely different.

There are three options:

• The supersaturation filling procedure can be accomplished by chilling the solution, while allowing for little or slight evaporation.

• Supersaturation can also be achieved by solvent evaporation with a little amount of cooling.

• Super saturation can be accomplished by a mix of cooling and adiabatic evaporation. This is sometimes referred to as vacuum crystallization.

To achieve the stringent standards for extracting zero liquid, a crystallizer is also required to decrease the concentration of the brine into a solid dry. The water may be recycled back into the plant's operations, while the solids can be securely disposed of in an approved waste disposal facility.

Applications of Zero Liquid Discharge Systems

• The crystallization process is employed in a variety of industrial applications. The crystallization method is frequently used to clean large amounts of liquid waste.

• It is beneficial when treated wastewater cannot be discarded.

• To treat polluted water when traditional methods fail.

• Cleaning of compressors and ground water.

• Concentrate on the materials.

Benefits of Zero Liquid Discharge Systems

• Reduces the quantity of waste that otherwise has to be controlled.

• Significant cost savings in waste management.

• Encouraging the reuse of a significant portion of the liquid.

• The likelihood of deploying a zero-discharge system.

• Compliance with current waste disposal requirements.

• Reducing the requirement for additional waste storage.

• Reducing the greenhouse gas (GHG) emissions from the waste transportation.

• Reusing clean water to reduce the consumption of piped water.

Conclusion

Zero-liquid discharge (ZLD) is a water treatment technique that purifies and recycles all wastewater, resulting in zero discharge at the conclusion of the treatment cycle.

Netsol Water provides zero liquid discharge technologies, such as membrane filtration, crystallization, ionization, and others to treat water and wastewater, in the most environmentally friendly way possible.