The majority of the seafood processing facilities are modest, with a few larger facilities situated close to commercial and populated areas. Processed seafood includes molluscs (oysters, clams, and scallops), crustaceans (crabs and lobsters), freshwater fish, saltwater fish, etc.

Similar to most processing businesses, the processing of seafood results in the production of wastewater that is highly contaminated in terms of soluble, colloidal, and particle pollutants. The level of contamination varies depending on the operation; it could be light (for example, washing activities), moderate (for example, fish filleting), or heavy (e.g., blood water drained from fish storage tanks).

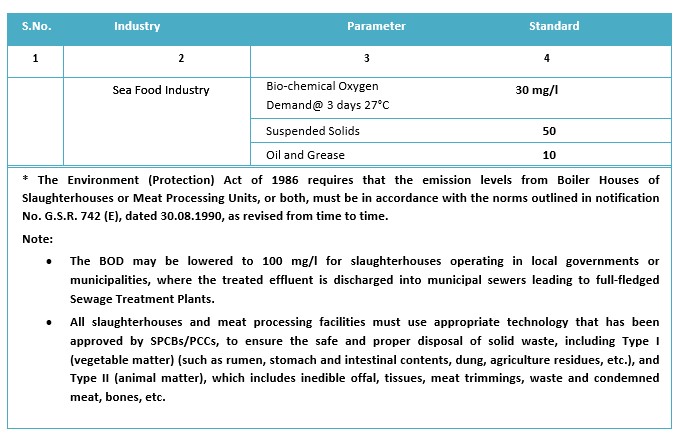

Before discharging this effluent into the rivers, or seas, it needs to be treated using Effluent Treatment Plants. Therefore, certain guidelines are provided by CPCB for effluent discharge into rivers or other bodies of water.

Characterization of wastewater from seafood processing

Pollutant parameters, process waste sources, and waste types are only a few of the aspects of seafood processing wastewater that might cause worry. In general, the physicochemical characteristics, organics, nitrogen, and phosphorus levels of wastewater from the processing of seafood, can be used to identify the wastewater.

The five-day biochemical oxygen demand (BOD-5), chemical oxygen demand (COD), total suspended solids (TSS), fats, oil, and grease (FOG), and water utilization are significant pollutant parameters of the wastewater.

CPCB Guidelines for ETP Plants in Sea food Sector

The contaminants found in wastewater from the processing of seafood, are an indeterminate mixture of primarily organic elements, as is the case with most industrial wastewaters. An overall measurement of the degree of contamination is sufficient because, a comprehensive examination for each component present is either meaningless, or practically unattainable.

Wastewater sources from seafood processing

Fish, shellfish, marine plants and animals, as well as by-products like fish meal and fish oil, are all involved in the processing of seafood. The procedures employed in the fish sector often include picking, eviscerating, pre-cooking, storing, receiving, etc.

Wastewater is produced from a variety of sources, such as fish storage and transportation, fish cleaning, fish freezing and thawing, brine preparation, machinery sprays, offal transportation, cooling water, steam generation, and equipment and floor cleaning.

Conclusion

Since, the impact is dependent on the effluent strength, discharge rate, and assimilation capacity of the receiving water body, it is challenging to generalize the size of the issue caused by these wastewater streams. Nevertheless, when defining the properties of a wastewater, important contamination parameters must be taken into consideration.

Effluent treatment plant manufacturer for seafood processing sector

Netsol Water offer a wide range of specialized services, including design, installation, and commissioning, for the effluent treatment plants. In order to assist you satisfy quality standards, and deliver the greatest output, our engineering team collaborates with your team. We offer practical solutions at very affordable prices, whether cooling tower water treatment, boiler water treatment, zero discharge, or other types of filtrations.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.