Overview

Secondary treatment of the wastewater is designed to substantially degrade the biological content of sewage. This could be achieved by chemical unit processes or by employing biological processes where bacteria are used as a catalyst for removal of pollutants.

Biological treatment processes are commonly used for removal of organic matter from the wastewater. Hence, for the secondary treatment of wastewater, the steps adopted will invariably consist of a biological reactor either in single stage or in multi stage as per the requirements to meet the discharge norms.

What is Contact Stabilization in Activated Sludge Process?

It is developed to make use of the absorptive properties of activated sludge process. The BOD is removed in activated sludge process in two phases.

Phase 1 - The absorptive phase: During this phase, most of thefinely divided suspended solids, colloidal and dissolved organic content, gets absorbed on the activated sludge. This requires 30 to 40 minutes

Phase 2 – Oxidation Phase: In this phase, the oxidation of organic matter occurs.

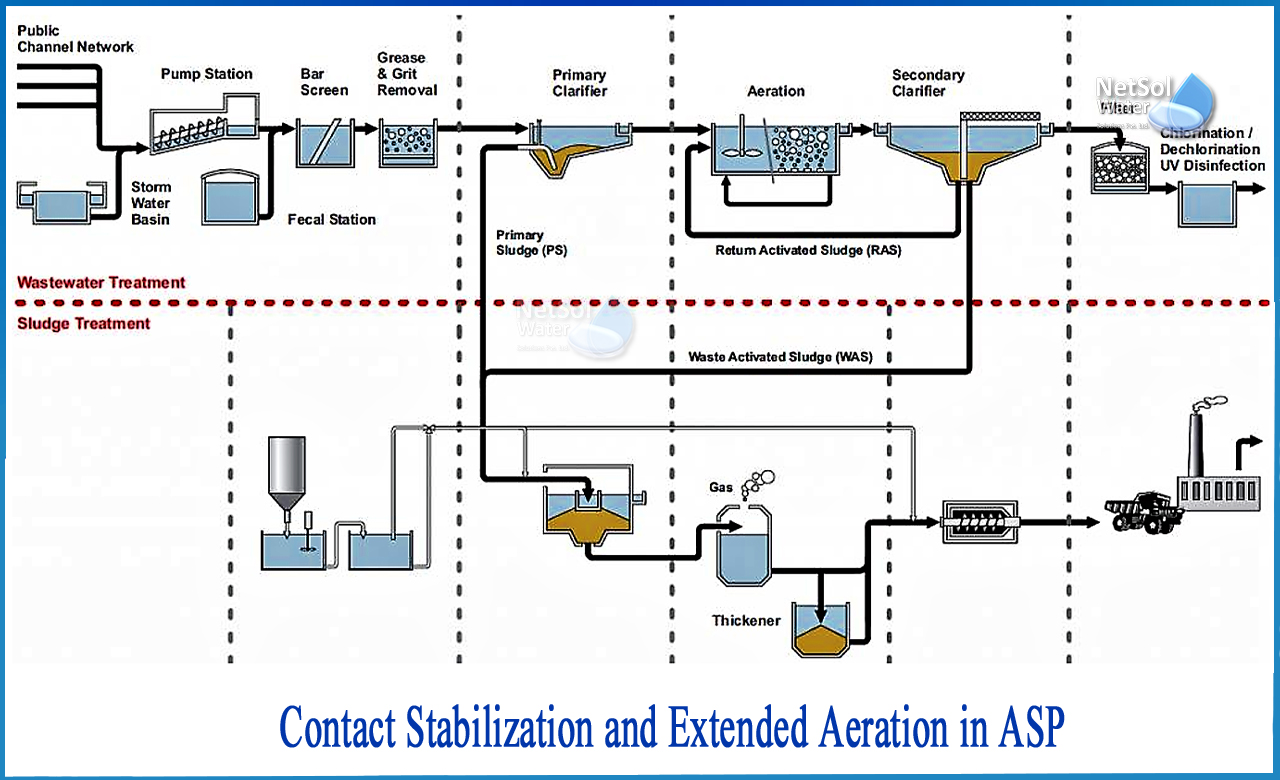

These two phases get separated out and they occur in two separate tanks in contact stabilization process. The settled wastewater is mixed with aerated activated sludge and aerated in the contact tank for a period of 30 to 90 min. During this period, the organic content is absorbed on the sludge flocs. The sludge with absorbed organic content is separated out from the wastewater in the SST. A portion of the sludge is wasted to maintain required MLVSS concentration in the tank. The return fraction of the sludge withdrawn from the settling tank is aerated before feeding it back to aeration tank for 3 to 6 h in sludge aeration tank. During the re-aeration of the sludge, absorbed organic matter is oxidized to restore the adsorptive energy and produce new cells.

The aeration volume requirement in this case is approximately 50% of the conventional ASP. The capacity of the existing ASP can be improved by converting it to contact stabilization. Minor changes in piping and aeration is required for this.

Contact stabilization is quite effective for treatment of sewage; however it is not very effective in treating the industrial wastewater where the organic matter present in the wastewater is mostly in the dissolved form. Modification of existing treatment plantscan be done by changing the piping and providing partition in the aeration tank. This upgradation will enhance the capacity of the existing plants. It will also be effective for sewage treatment because of presence of organic matter in colloidal form. This process may not be that effective for the treatment of wastewater containing organic matter only in soluble form.

What is Extended Aeration?

Extended aeration process is one of the modifications of Activated Sludge Process (ASP). This system includes aeration and mixing, settling, sludge return and removal of solids.

It is a complete mix process providing biological treatment to wastewater for the removal of biodegradable organic wastes under aerobic conditions. Mechanical or diffused aeration are used to provide the oxygen required to sustain the aerobic biological process. Mixing is done to maintain the contact of microbial organisms with the dissolved organics. Since there is complete stabilization in the aeration tank, there is no need for separate sludge digester.

Primary sedimentation tank is also discarded and settleable organic solids are also allowed to settle in the aeration tank due to long detention time in the aeration tank. It employs low organic loading rate (F/M), long aeration time and high MLSS concentration. Due to long detention in aeration tank,the cells undergo endogenous respiration. The excess sludge generated in this process is low and does not require separate digestion and the sludge can directly be applied on the sand drying beds where aerobic digestion and dewatering of the sludge occurs.

How can Netsol Water help you?

Netsol Water is one of the leading water and wastewater treatment company in India with services in the field of WTP manufacturing, WWTP manufacturing, STP manufacturing, among other services. The company designs and manufactures all in one systems that are ideal for treating wastewater and the sludge generated and not only turns your wastewater into usable water but also acts as a savior of Mother Earth and its precious resource “water”.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.