Complete Knowledge About Sewage Treatment Plant

Sewage treatment plants accept waste from residential, commercial, and industrial sources and treat it to eliminate toxins harmful to water quality and pose a risk to public health and safety when released onto land or into receiving systems. It is a group of unit activities and unit processes created to meet the effluent criteria of the regulatory body and treat sewage to acceptable standards.

The necessity of the sewage treatment plant has introduced itself so well that it needs no more introduction, but many questions arise regarding the sewage treatment plant. For the same reason, this article is designed. Here, we will be answering some fundamental questions arising in one’s mind before installing sewage treatment plants. So, let’s get started.

What is the life of a sewage treatment plant and How to increase the life of your sewage treatment plant?

Sewage treatment plants are typically designed to have a 25-30 years lifespan. However, with proper maintenance and periodic upgrades, the functional life can be extended significantly past the initial design life. Believe it or not, sewage treatment plants don’t require much upkeep. Let’s learn some of the fundamental ones.

Why is it mandatory to install STP for housing societies and industries?

You almost assume that the government would ensure the water supply is clean before it reaches our homes, so you rarely think about your local freshwater lake that smells like rotten eggs or a riverbank covered with brown debris. Housing societies produce abundant amounts of sewage daily from thousands of residents. Installing compact STPs with sequencing batch reactor technology allows complete treatment and recycling within society premises. Similarly, industries dealing with chemical contaminants require isolating their effluent streams for individualised treatment. Regulated pre-treatment via captive effluent treatment plants containing neutralisation tanks, oil separators, activated carbon filters, and other tertiary treatment ensures factories only contribute clean discharge into the standard conveyance system.

Then, you tend to think your kitchen tap is clean because the same water is running through it, but is it? India's major cities—aside from Mumbai—failed the Bureau of Indian Standards' test for water quality.

What now? You would say, "We install water purifiers and buy mineral water anyway; we don't drink tap water," without addressing the issue's root.

Like the world's most developed nations, we would have clean water that is suitable for human consumption right out of the tap if our rivers and lakes were never contaminated in the first place and if each of us cleaned up our mess instead of throwing it on the earth and its precious water source. The treatment and management of water in big cities is an unimaginable nightmare.Untreated sewage accounts for an astonishing 70–80% of the total wastewater in India, a country of 135 billion people, and is the country's leading cause of water pollution.

"In several cities, the existing treatment capacity remains underutilised while a lot of sewage is discharged without treatment in the same city," said a study by the Central Pollution Control Board. According to official inventories, India has less than a thousand sewage treatment plants.

In summary, we must consider private wastewater treatment alternatives, such as sewage treatment plants or STPs.

Why should I install sewage treatment plants and What are the Govt norms for installing sewage treatment plants in Noida?

Noida is one of India’s fastest developing urban centres, with numerous residential complexes and commercial buildings sprouting rapidly amidst rising population pressures. However, an essential requirement accompanying all the habitats is sufficient decentralised sewage treatment infrastructure.

The city lacks a fully functional underground sewer network. Additionally, Noida’s trunk sewer system partially connects to Delhi’s overstressed sewage network, ultimately discharging excessive pollution loads into the Yamuna River. The Yamuna remains devoid of dissolved oxygen for over 60% of its length due to excessive organic contamination. Hence, onsite handling of sewage is of utmost importance.

Housing developments larger than 20,000 square meters in major cities are approved only if they handle solid waste internally, which means that they must have operational and compliant private solid waste treatment plants. But the builder is in charge of the installation at the design level and has to keep it maintained for five years after occupants move in.

Since 2015, sewage treatment standards have been relaxed, revised, and finally strengthened in 2019. Here's a brief but clear synopsis.Strict regulations on effluent discharge were implemented by the Central Pollution Control Board in 2015; these laws limited the quantity of pollutants that may be permitted to be re-released into water bodies. Higher pollution wasallowed in 2017 due to a relaxation of the rules. Concurrently, research conducted by the CPCB, IIT Roorkee, IIT Kanpur, and NEERI revealed that weaker regulations deteriorated river water quality. The National Green Tribunal (NGT) eliminated the loosened regulations in 2019 and reinstated strict guidelines about treated wastewater. New and old STPs in megacities and metro areas must now adhere to the updated guidelines listed below.

Fecal Coliform: 230 per 100 milliliters;

BOD (Biochemical Oxygen Demand) level: 10 mg/L;

pH value: 5.5–9.0;

Total Suspended Solids: 10 mg/L;

Nitrogen: 10 mg/L;

COD (Chemical Oxygen Demand): 50mg/L.

How to Select The Best Sewage Treatment Plant (STP) Technology to Treat The Sewage?

Choosing the optimal STP technology depends on various factors, like

1- The nature of sewage needing treatment,

2- Discharge standards needing compliance,

3- Capital plus operational costs,

4- Availability of land,

5- Desired treated water quality and

6- Skill level of plant operators.

Here are the name of a few most successful Technologies of Sewage Treatment Plant

1) MBBR

2) MBR

3) SBR

4) Underground MBBR Tecgnology

Conventional technologies like activated sludge processes with secondary clarification are economical, widely understood, and incorporate biological organics oxidation and nutrient removal. However, membrane bioreactors integrate ultrafiltration membranes for higher quality water, albeit costs rise manifold. Moving bed biofilm reactors employ specialised media providing efficient oxygen transfer for compact aerobic plus anaerobic treatment. They suit small footprint installations yet require more excellent operational knowledge. Operators must also judiciously select tertiary polishing based on faecal coliforms or other regulated parameter thresholds in the discharge permits - methods like oxidation, coagulation, granular filtration, or disinfection using chlorine, UV, or ozone. Pilot testing of the selected technology is ideal before the final design to evaluate on-the-ground performance for the intended sewage characteristics and treatment needs. Economic modeling, including capital, operating, and maintenance costs, indicates the financial viability and helps appropriately size the STP technology.

How much time it takes for installation and commissioning to set up sewage treatment plant?

It's no secret that constructing a sewage treatment plant might take months, Two months or even years. Total depend on the size of Sewage Treatment Plant. The overall operation consists of many steps that clean the sewage of impurities. Sewage treatment plants require careful planning, design optimisations and equipment procurement before civil construction can begin on site.

If the vendor and client's technology selection and approval design agreements conclude swiftly within 1-2 months, actual STP installation generally takes 4-6 months, depending on the treatment capacity and complexities involved. Civil works like excavations, tank building, pipeline laying, electrical fittings, and instrumentation wiring take the bulk of time. After that, around 1-2 months go towards equipment installation, calibrations, and trial runs before consistently treated effluent quality signifies a successfully commissioned STP. On average, clients should budget 6-8 months from design finalisation to when the vendor operationally hands over the fully functional sewage treatment plant matching all specified discharge parameters for the client’s infrastructure needs and pollution control board’s consent conditions. Timely decisions, prompt payments, and location readiness from the client’s end, coupled with quality construction from the vendor’s side, ensureadherence to the commissioning timelines for the STP.

What is the size of STP Plant and How does it look like and How can you reduce the STP installation area, so it takes less area for installation?

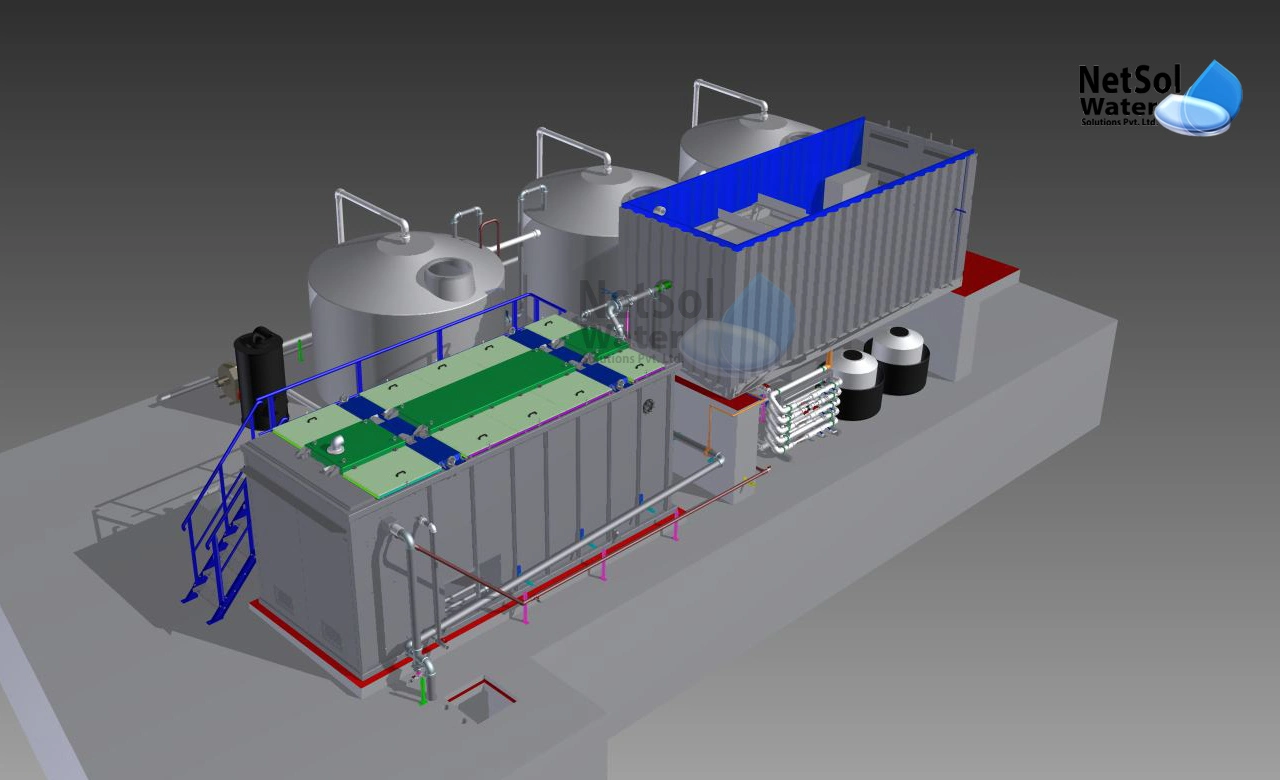

The size of an STP can vary substantially from serving just a few households to entire towns. A small STP may have a total footprint of around 20 sq. ft., while a large-scale STP can occupy acres of land with numerous treatment components spread out. Generally, STPs contain bar screens, aeration tanks, collection tank, clarifiers, sludge digesters, and other units that provide mechanical, biological, and chemical treatment. Multiple concrete tanks/basins with associated pumps, pipes, and instrumentation wiring make up the core appearance.

Here are belwo example of compact STP Plants size –

10 KLD - 12-15 Square Meter

20 KLD - 16 -20 Square meter

50 KLD - 35-40 Square Meter

80 KLD - 50 -55 Square Meter

100KLD - 75-80 Square Meter

200 KLD - 125 Square Meter

300 KLD – 170 – 190 Square Meter

500 KLD - 300 Square Meter

800 KLD - 400 Square Meter

1000 KLD – 600 Square Meter

To minimise an STP's installation area:

1- Employ compact technologies like SBRs (sequencing batch reactors), MBBRs (moving bed biofilm reactors) or membrane bioreactors rather than conventional activated sludge processes which occupy more space.

2- Optimize the treatment plant layout to reuse land for multiple functions. For example, using underground tanks below landscaped parks.

3- Stack treatment modules vertically using pumps rather than spacing them out horizontally.

4- Use higher efficiency components like air/water diffusers, decanters, blowers, etc., to minimise tank volumes.

5- Apply appropriate scaling factors when estimating capacities to avoid grossly oversized STPs requiring more land.

6- Construct underground pipelines to interconnect the STP units or nearby locations, avoiding land exclusively for piping.

With available land being the limiting factor today, especially in urban environments, compact STP construction is essential and achieved using advanced treatment methods coupled with efficient design. This allows for the comfortable fitting of the sewage treatment plant even into congested community premises.

How to calculate STP(sewage treatment plant) capacity?

Here are the key steps to calculate the capacity of a sewage treatment plant (STP):

1- Estimate the population to be served by the STP over its lifetime (typically 30 years). Include expected population growth.

2- For Socities / Group housing Buildings Determine the wastewater generation rate per person per day. A typical assumption is 100-150 litres per capita per day.

3- For Corporate Buildings/ manufacturing industries waste water generation is 45 Liter per person per day. User should calculate the capacity for their organisation according to this

Account for sufficient safety factors and maximum population growth so that the STP does not get overloaded in its intended lifetime. The capacity should account for organic and hydraulic loading likely to enter the plant including losses, shocks and future margins.

What percentage of sewage water gets treated in Noida and in Delhi NCR?

Delhi, the capital city of India, which is situated in northern India, as of 2023, was almost 35 million people. This was a 2.73 per cent growth from last year. Since 1971, the population has increased by more than 300%. By 2050, it is expected to grow to 72 million, or 44% of the current population.According to the Delhi Development Authority's master plan, the country's water needs and wastewater production will be 6674, 5340 MLD in 2011, 8365, 6692 MLD in 2021, and 19728, 17750 MLD in 2050. Only 512.4 MGD of the approximately 600 MGD of sewage that Delhi alone produces each day can be treated by the sewage treatment plants already in place.

In Noida specifically, there are capacities to treat around 85% of the over 200 million liters per day of sewage generated in the city. However, actual treatment levels are lower, with estimates ranging from 50-60% of Noida's sewage receiving adequate treatment before discharge. The situation is similar in Delhi, where installed treatment capacities of around 50% of sewage generated are not fully utilized, and 30-40% of waste water gets actually treated. Overall, while infrastructure exists, utilization and proper functioning of sewage treatment plants remains a challenge across NCR. Enhancing budgets, management, and monitoring of facilities could improve matters and help treat a higher proportion of the region's wastewater.

What does sewage or sewage water contain?

Although it's commonly used to refer to any wastewater, Sewage or sewage water refers to the wastewater from residential, institutional, and commercial establishments that is collected through sewers. It contains various components:

1- Organic matter - This includes food leftovers, plant matter, paper fibres from toilet paper, etc. As it decays, it causes foul odors and consumes oxygen.

2- Pathogens - Sewage contains disease-causing bacteria, viruses, protozoa, and intestinal parasites that can cause illnesses like cholera, typhoid, dysentery, etc.

3- Nutrients - It contains high levels of nitrogen, phosphates, and other nutrients from food, soaps, detergent, etc. This can cause eutrophication and algae blooms if untreated sewage is discharged into water bodies.

4- Toxins - Sewage may contain small amounts of chemicals, heavy metals, pesticides, oil and grease, drug residues which can be harmful.

5- Suspended solids - It contains sand, grit, slits which need to be removed before releasing treated wastewater in the environment.

Proper sewage treatment is essential to remove these impurities and pathogens before the water can be reused or safely discharged back into the environment.

How to get NOC No objection certificate or Consent to establishment andconsent to operate from pollution control board for your sewage treatment plant or Effluent Treatment Plant?

Global governments are becoming increasingly concerned about sustainable development. Due to environmental exploitation, contamination of water bodies, and poor water quality. NOCs are required by the Indian government to ensure that industries do not contaminate their surroundings.

The best way to get NOC is to conncet the Local Pollution control Board Office, since there are some documents required to process the CTE ( CONSENT TO ESTABLISHMENT AND CONSENT TO OPERATE )

Here are the key steps to obtain No Objection Certificate (NOC) / Consent to Establish and Consent to Operate from the Pollution Control Board for a Sewage Treatment Plant/Effluent Treatment Plant:

1. Apply to the relevant State Pollution Control Board with details of the proposed project like location, capacity, treatment processes, layout, discharge points etc. along with prescribed fees.

2. The Pollution Control Board will review the application and may undertake a site visit to assess potential pollution impact.

3. For Consent to Establish, provide additional details when requested like environmental management plans, projected effluent quantity/quality data.

4. Obtain NOC from relevant groundwater, irrigation department etc. if required by the Board.

5. Incorporate any modifications suggested by the Board, such as changes in treatment steps, discharge standards, etc.

6. After verification, the Board issues Consent to Establish allowing construction/installation of the plant.

7. After completion, apply for Consent to Operate by providing an engineer's plant completion report and results of trial runs demonstrating treatment capacities and discharge quality.

8. The Board will verify the actual performance of the functioning plant and check for compliance through monitoring & inspections.

9. If found satisfactory, the Pollution Control Board will issue Consent to Operate with terms & conditions for running the plant.

Adhering to the Pollution Control Board's norms and timely applications at each stage helps obtain NOC and consent orders smoothly. The process ensures sewage treatment plants meet all compliance standards before starting operations.

Civil constructed sewage treatment plant vs MS Compact sewagetreatment plant: which one is better?

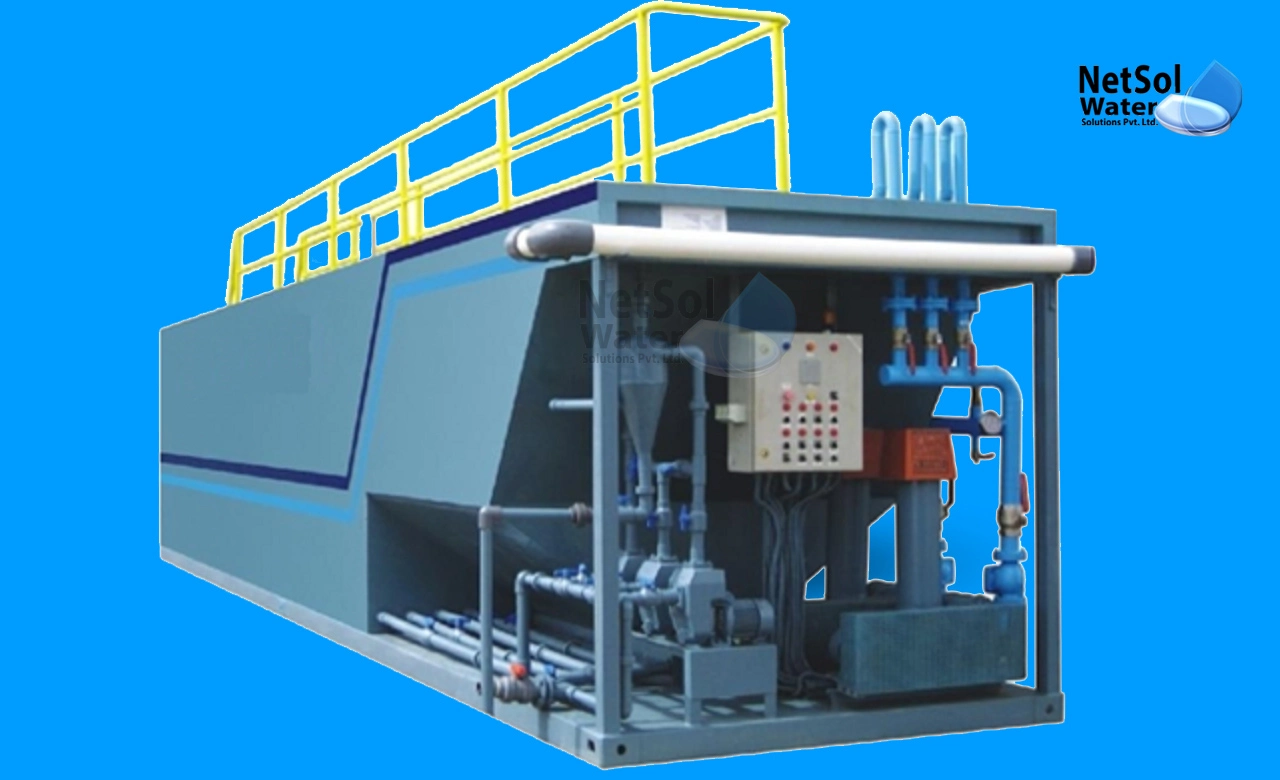

Civil Constructed STPs: Civil-constructed sewage treatment plants (STPs) refer to facilities custom-built from the ground up using traditional masonry construction and civil works where they will operate. They consist of structures like bar screens, collection tanks, anaerobic/aerobic digesters, clarifiers, sand filters, and chlorination tanks made using local building materials by trained construction crews. Being made on-site, they can be tailored to meet specific sewage treatment needs.

MS Compact STPs: Modular or MS (mild steel) compact sewage treatment plants consist of pre-engineered treatment systems made from anti-corrosive materials manufactured in a factory and installed on prepared platforms by technical specialists at the project location. They occupy less space than traditional STPs and utilise advanced processes integrated in compact, plug-and-play units to meet stringent discharge standards while requiring less maintenance. The modular components offer flexibility for capacity expansion when needed. Top suppliers provide technical support.

Both civil-constructed and modular MS (mild steel) compact sewage treatment plants have their pros and cons:

Civil constructed STPs:

Pros:

1· Can be custom-designed and built to meet specific site needs

2· Durable structure with a longer lifetime

3· Skilled local labour may be available for construction and maintenance

Cons:

1· Require high capital and construction time

2· Prone to leakage over time; requires regular civil maintenance

3· Occupy more space and have fixed treatment capacity

MS Compact STPs:

Pros:

1· Faster installation with limited site work needed

2· Modular components allow flexibility to modify or expand capacity

3· Compact, anti-corrosive, leak-proof, and low-maintenance

4· Advanced treatment processes can meet strict discharge norms

Cons:

1· Limited to standard available capacities and designs

2· Require mechanical parts replacement over time

3· Need specialised technical support for O&M

In summary, for long-term, higher-capacity applications with space availability, civil-constructed STPs may be suitable. Pre-engineered MS STPs can be a better option for faster implementation, compact footprint, and advanced treatment. Site-specific factors ultimately determine the optimal type to adopt. Hybrid models also make it possible to leverage the benefits of both technologies.

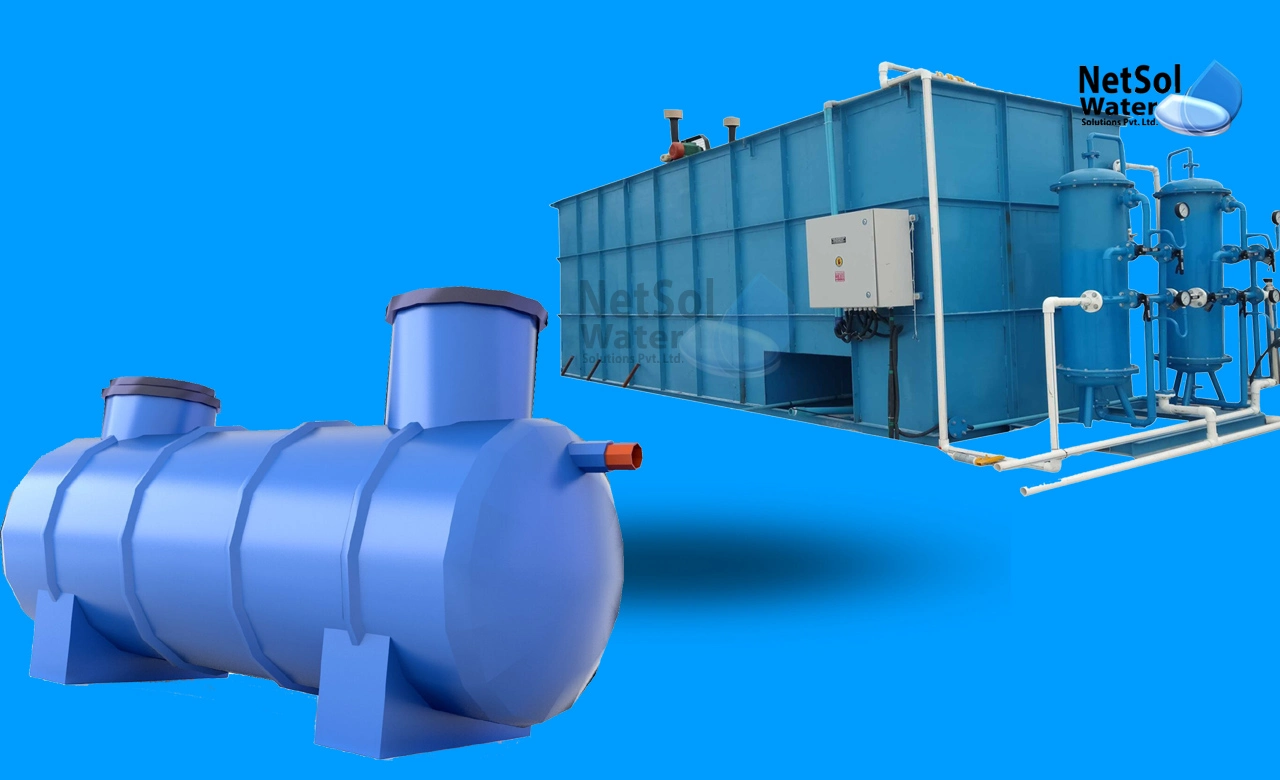

Underground sewage treatment plant vs. above-the-groundsewage treatment plant and Comparison between both, which one is betterand why?

So, the debate between Underground and above-the-groundsewage treatment plants may not be fascinating. Still, if you own a property with an off-main drainage system or are considering purchasing one, it's essential to understand the differences.Here is a comparison of underground and above-ground sewage treatment plants:

Design and Construction:

1- Underground STPs require waterproofing, durable lining and corrosion-resistant materials as structural elements surround sewage. Above-ground STPs have lower construction requirements.

2- Underground STPs call for extensive excavation, shoring and pumping out of groundwater, substantially increasing costs. Above ground is more straightforward and economical to build.

3- Above-ground STPs occupy usable land space, while underground STPs leave land above available for other productive uses once constructed.

Operations and Maintenance:

1- Undergone STPs protect from weather events but make visual inspection and detection of leaks difficult. Monitoring and repairs require specialised confined space protocols. Above-ground STPs allow easier visible oversight.

2- Underground facilities experience accelerated deterioration over time due to dampness, gases and lack of ventilation. This necessitates higher maintenance than equivalently sized above-ground STPs.

Environmental Impact:

Underground STPs have lower noise, odour, and landscape impacts, making them better suited for urban areas or close to communities. Above-ground STPs require mitigation measures to minimise nuisance, especially odour.

In short, above-ground STPs are typically preferred for lower capital and operating costs, ease of operations, and better maintainability. But underground STPs are chosen where land scarcity or community impacts are critical project considerations despite higher price tag. A combination of both also finds application.

Does STP give foul smell and Why does it give the foul smell and how tocope with this?

Yes, sewage treatment plants (STPs) tend to give foul smells due to the nature of the waste they handle and the treatment processes involved. One of a sewage treatment facility's most crucial and challenging aspects is odour control. Often, unpleasant odours are what set off the neighbour's protests.

Let's first examine the reason of the stench at sewage treatment facilities to determine how to address it.

Reasons for Foul Smells:

1- Raw sewage has an unpleasant odour due to decaying organic matter and gases like hydrogen sulfide. This persists through early treatment stages.

2- Anaerobic processes like sludge digestion relied on in STPs release gases like ammonia, hydrogen sulfide, and volatile acids that cause offensive rotten egg or cabbage smells.\

3- Algae growth in treatment tanks and poor aeration can create additional unpleasant odours.

Mitigation Approaches:

1- Covering raw sewage inlets/outlets, headworks screen channels, and sludge tanks to contain odours. Venting these concealed units to odour control units.

2- Chemical dosing uses oxidising agents on sewage to dampen the release of volatile gases.

3- Adequate facilities, ventilation,and negative air pressure zones to avoid odour offsite migration.

4- Odor control units with absorption, adsorption or biofilter odour-causing compound-causing compounds.

5- Automated monitoring and audit procedures for prompt action on process disruptions.

6- With containment, plant process & capacity optimisation and tail-end treatment methods, sewage treatment facilities can significantly reduce odour issues.

7- One further important thing to realise is that different smells have different intensities.

Additionally, the smell is made stronger by the weather. Inversions in temperature, wind speed, and wind direction, for example, are essential factors in drifting odor emissions. Generally speaking, it gets worse in warmer weather. As a result, complaints over the odor are common in the summer.

How many sewage treatment plants are installed in Noida and in Delhi NCR, kindly write with the help of data?

Regarding how STP operates, Noida city is divided into four zones: A, B, C, and D. There are 53 sectors and 8 villages in the first zone (A), while there are 18 sectors and 4 villages in the second zone (B). There are 28 sectors and 9 villages in Zone C and 33 industries and 91 villages in Zone D, respectively.Here are some key details on the number of sewage treatment plants (STPs) in Noida and the National Capital Region (NCR) of Delhi:

Noida:

As per official records, Noida has 11 sewage treatment plants across the city with a cumulative installed capacity to treat 367 MLD (million litres per day).

The major Noida STPs include Sector 50 plant (45 MLD), Sector 123 (25 MLD), Noida Phase I (78 MLD), and Sector 108 plant (20 MLD). Several decentralised plants also support localities.

However,some reports estimate that only 195-215 MLD get operationalized, given infrastructure constraints. This, too, falls short of the city's 300+ MLD of sewage.

Delhi NCR:

Delhi has 35 STPs totalling around 2900 MLD installed capacity. But nearly 40% of the city's sewage flows into untreated river bodies, as per CPCB estimates, indicating massive underutilisation.

In other NCR cities, Gurugram claims 429 MLD in STPs, Ghaziabad 210 MLD and Faridabad 225 MLD capacity. However, effectiveness in practice remains a lingering concern.

Overall, while infrastructure capacity exists on paper, significant gaps in sewerage coverage and underperformance of aging plants result in excessive discharge of untreated sewage across NCR - an issue needing urgent collective action.

How to use sewage water for construction purpose in Noida?

With freshwater resources under pressure, treating sewage water is gaining prominence for appropriate non-potable applications. In Noida's case, its several Sewage Treatment Plants (STPs)output nearly 200 MLD water daily that can serve such “reuse” needs, that treated water from STP is getting used for construction purpose.

Groundwater levels in most Greater Noida are in the "critical" zone. According to a study by the UP Groundwater Department, the water table dropped from 6.66 meters in 2016 to 12.75 meters in 2020, a decrease of around 6.09 meters.The sewage departmentstated: "Purchasing treated water for development projects from STPs is not costly. Anyone wishing to get purified water can apply at the authority's front desk or water department.

All this gives a glimpse of the compulsion to use sewage water for construction purposes in Noida.

Regulations allow builders in Noida to use this processed wastewater for construction by obtaining approval from authority and arranging regular supply from nearby STPs.After onsite storage and quality checks, this nutrient-rich wastewater is applied for soil compaction, concrete curing, dust suppression and equipment cleaning as process requirements. Monitoring usage norms as per NPCC standards minimises health/environmental risks. The practice serves dual objectives in water-scarce regions, such as reducing sewage discharge into rivers and cutting freshwater usage for construction. As sewage infrastructure expands in Noida to treat higher proportions of its 300+ MLD generation, more construction reuse avenues open up via coordination between builders and civic agencies.

Here are the key steps to use sewage water for construction purposes in Noida:

Obtain Approval:

Seek approval to use treated effluent from Noida Authority's Public Health Department or alternatively the contractor can directly coordinate with Noida Jal Board.

Source Treated Water:

Make arrangements to source the treated sewage water in bulk from nearby Sewage Treatment Plants in Noida.

Set Storage Infrastructure:

Set up storage tanks, plumbing, and hauling infrastructure at the construction site to receive and retain the obtained sewage water.

Carry Out Tests:

Send samples for lab tests to analyse parameters like BOD, nutrients, and total dissolved solids to check compliance with NPCC standards for construction-use class SW-II waters.

Allowed Applications:

Apply stored treated sewage water for limited construction purposes like soil compaction, concrete curing, equipment cleaning and dust suppression within the site.

Following NPCC guidelines and requisite safe handling practices for STP water helps promote reuse and reduces freshwater demands for construction in water-stressed regions like Noida. Obtaining ready supply from Noida's expanding sewage treatment capacities is key.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best sewage treatment plant manufacturer and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.