What are the different methods of aeration process?

The use of oxygen in aeration procedures for wastewater treatment aids in a natural biological process. Companies and municipalities that need to treat wastewater for disposal or reuse can choose from a range of aeration procedures.

The activated sludge process (ASP), sequencing batch reactor (SBR), sequencing batch bioreactor (SBBR), membrane bioreactor (MBR), and moving bed biofilm reactor(MBBR) will all be discussed in depth in this article.

Each of these procedures has its own set of benefits and drawbacks. MBBR takes use of the advantages of aeration procedures while also providing unique features that sets it apart from other aeration methods. MBBR allows users to successfully treat wastewater for organic pollutants, as well as perform nitrification and denitrification, all while achieving a high degree of efficiency.

What is ASP aeration?

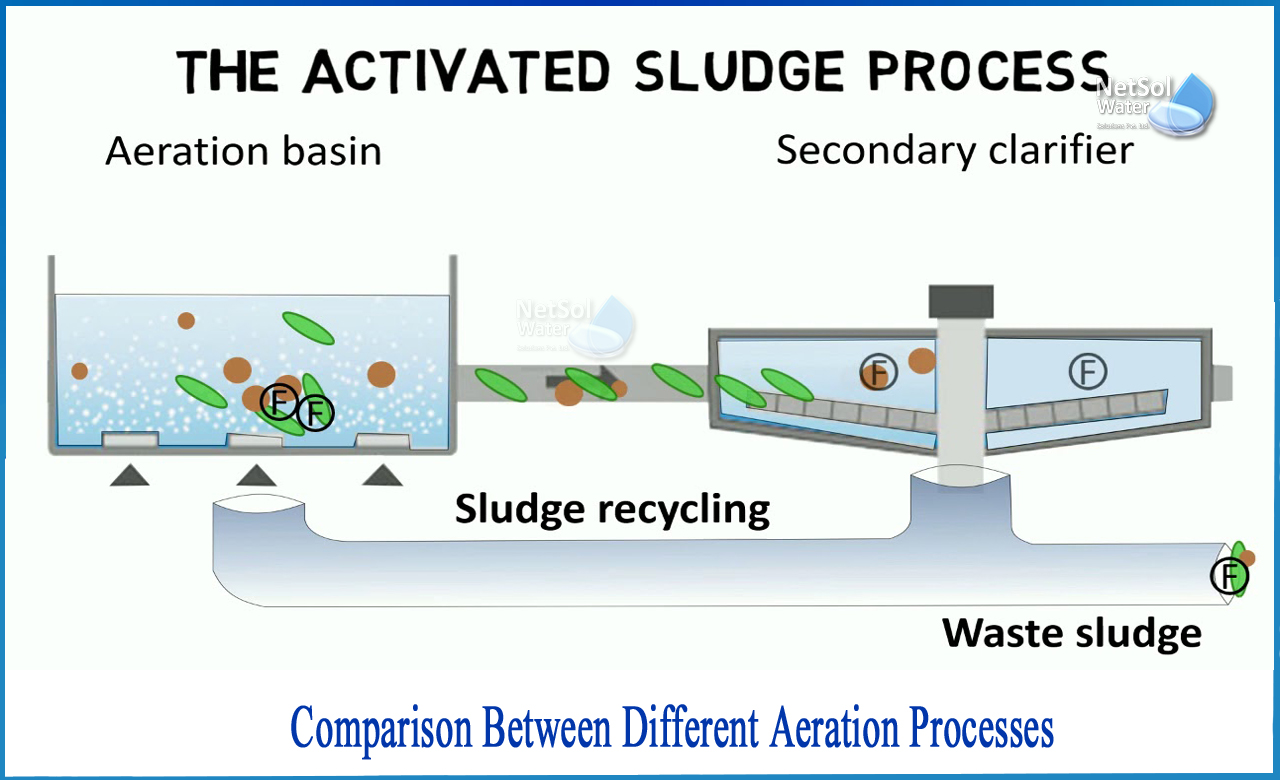

The activated sludge process (ASP) is the most prevalent aeration method for treating wastewater. Many people still believe the present version of the ASP method to be the conventional technique of biological wastewater treatment, despite the fact that it was invented little over a century ago by researchers. To remove sludge from wastewater, this technique employs aeration and floc.

What is SBR aeration?

An activated sludge process is identical to a sequencing batch reactor (SBR) aeration system. The main distinction is that instead of utilising different equipment for each stage in the process, this system employs a single tank for all of the treatment procedures. SBR employs time rather than space to achieve its wastewater treatment goals, as the word "sequencing" implies. According to the Environmental Protection Agency, this sort of system dates back to 1914. Batch reactors that can be sequenced are still in use today.

What is SBBR aeration?

The sequencing batch bioreactor (SBBR) is a newer innovation that aims to improve on the old SBR method. SBBR's purpose is to speed up the aeration step in order to treat wastewater with a shorter hydraulic retention time (HRT). The SBBR technique does this by combining SBR with a biofilm reactor. Because of its benefits over the normal SBR process, the SBBR method has received a lot of attention in recent years.

What is MBR aeration?

A membrane bioreactor (MBR) is a wastewater treatment method that contains a membrane process with a biological treatment approach based on suspended growth. The membrane is typically low-pressure microfiltration, with an activated sludge process for suspended growth. The first commercial application of this combined system was in the late 1960s, when it was used to treat wastewater on ships. MBR technology has grown in popularity for wastewater treatment of all sorts since its inception.

What is MBBR aeration?

Finally, there is one more novel aeration method to investigate: the moving bed biofilm reactor (MBBR). The biofilm linked to thousands of tiny plastic media in this technique, invented in the late 1980s and early 1990s, decomposes waste prevalent in influent in an aeration tank. The microbes in the tank may naturally adjust to variations in the kind and amount of waste in the water, therefore MBBR requires some monitoring but is mostly self-moderating.

Netsol delivers the greatest water treatment in India, including RO, distillation, aeration, STPs, ETPs, and others. Netsol Water offer RO systems that may be customised to fulfil a range of specific needs. Pre- and post-treatment methods are also available.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.