How to Classify of Membranes Based on Morphology and Geometry?

Membrane technology can treat a wide range of wastes, including sanitary landfill leachate containing both organic and inorganic chemical species, water-soluble oil wastes used in the metal fabricating and manufacturing industries, solvent-water mixtures, and oil-water mixtures generated during metal fabricating facility washing operations.

Membrane processes can be classified into sub-processes based on the material used for the membrane, the nature of the driving force, and the separation mechanism, such as reverse osmosis (RO), electrodialysis (ED) or electrodialysis reversal (EDR), microfiltration (MF), ultrafiltration (UF) and nanofiltration (NF).

Pressure is used to transfer water through the membrane in RO, MF, UF and NF. As water passes across the membrane, MF eliminates particle debris, whereas RO removes numerous solutes. Large particles and bacteria are often rejected by MF membranes, which have the biggest pore size. Because UF membranes have narrower holes than MF membranes, they can reject bacteria and soluble macromolecules like proteins in addition to big particles and germs. RO membranes are virtually non-porous, allowing particles and even numerous low-molar-mass species like salt ions and organics to pass through. NF membranes, also known as loose RO membranes, are a relatively novel kind of membrane.

Rising regulatory pressure to deliver higher quality water, increased demand for water necessitating the use of low quality water resources as a source, and the development and commercialization of membrane processes are the driving reasons behind the usage of membrane technology.

Membrane operation provides the following advantages-

- Separation occurs at room temperature with no phase change.

- There is no product build-up inside the membrane (unlike ion exchange resins, which require replacement/regulations).

- Chemical additives are not required for separations.

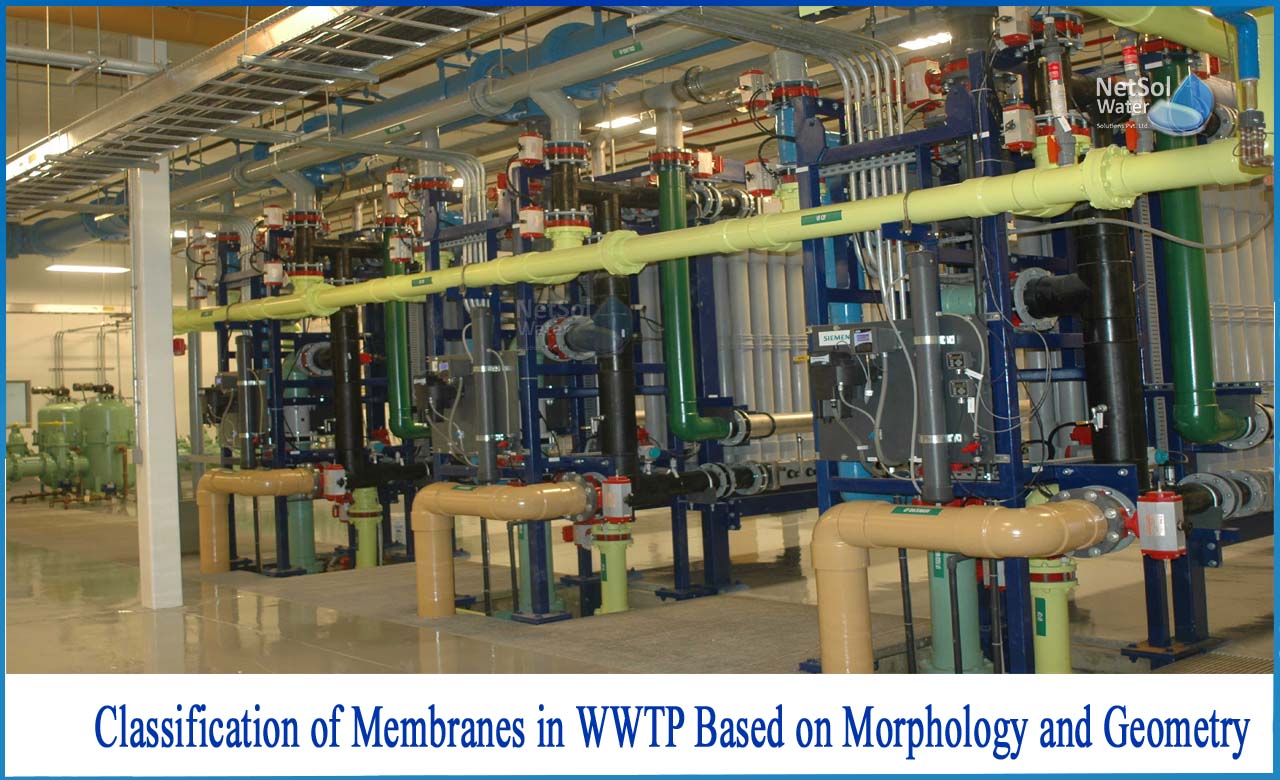

Membrane classification: Classification based on morphology

1: Asymmetric membranes

These membranes are anisotropic and made of the same substance.

2: Composite membranes

These are anisotropic membranes with distinct materials for the top layer and sub-layer. Each layer may be tweaked separately. Asymmetric membranes are the most common porous layer.

Membrane classification: Classification based on Geometry

Membranes are categorized as flat sheet membranes or cylindrical membranes based on their shape. Tubular membranes with an internal diameter greater than 3 mm and hollow fiber membranes with an internal diameter less than 3 mm are two types of cylindrical membranes.

They come in a variety of outer diameters, ranging from 80 to 500 meters. They're employed in larger-diameter RO. MF and UF also employ hollow fiber membranes, which are also known as 'capillary membranes.'

Conclusion

Membrane techniques for wastewater treatment are becoming more popular across the world as the cost of the procedure decreases and the cost of water rises. Membrane procedures accounts for over 70% of the total installed capacity of desalination across the world, and the percentage is growing (for drinking water).

In Japan, more than 30 MLD of wastewater is used in constructing toilet flushing water. It's used in a lot of industrial wastewater treatment plants to make reusable grade water out of the effluents. Membrane technologies should be adopted worldwide and that is what we are trying to do at Netsol Water.

How can Netsol Water help?

If you need help designing an efficient membrane technology equipment such as RO, contact Netsol Water. We are the leading manufacturers of the RO plants. We can provide you with design calculations, budgetary expenses, preliminary layouts, and a lifetime cost analysis.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.