Introduction

Many industries have been pushed to reconsider their approach to water management, due to the rapid depletion of water supplies in nationslike,India, which are facing a water crisis. Indian authorities have also passed legislation to increase water recycling, and lower the discharge of tainted industrial wastewater, as a result of the country's evolving pollution problems.

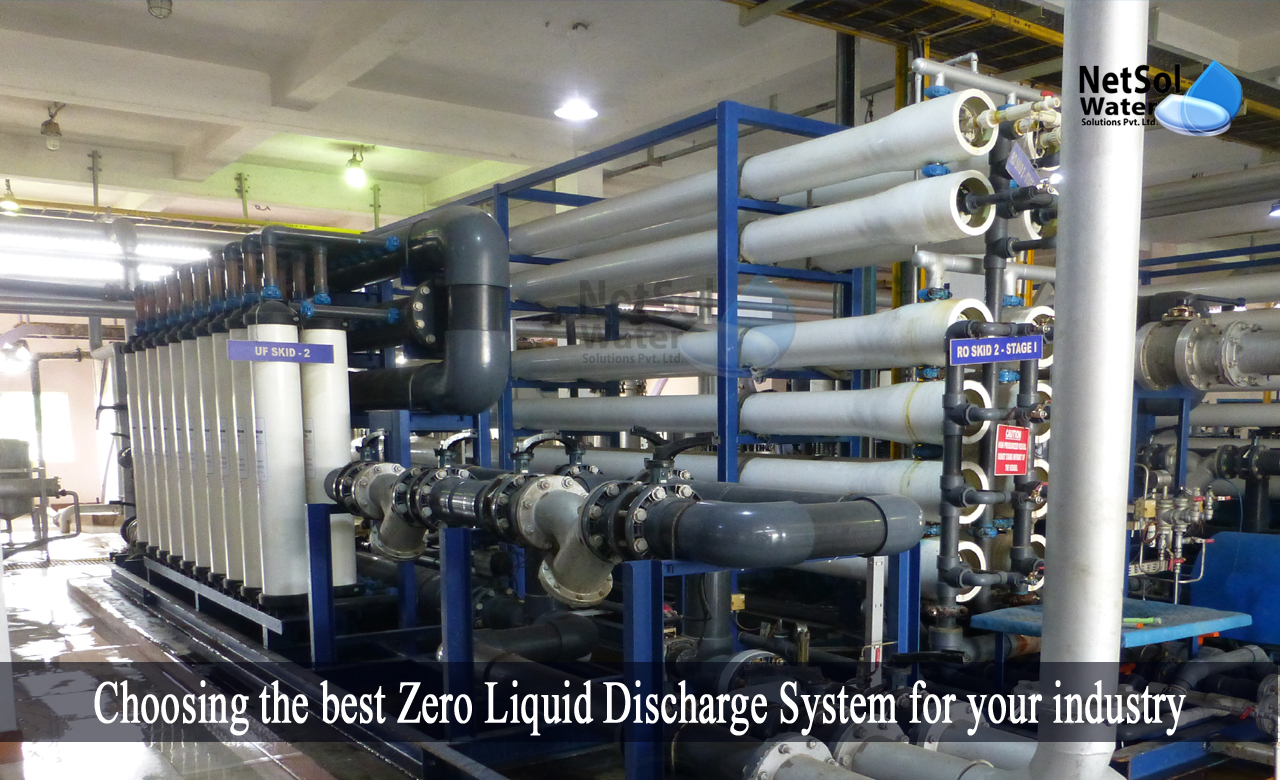

Zero Liquid Discharge (ZLD) wastewater treatment can increase water recycling, recover valuable resources, and stop the discharge of contaminated wastewater. But there are a number of crucial variables to take into account before putting a ZLD system into place.

How to choose the best ZLD System for your industry?

The equipment’s that will make up the system and the technologies utilized, will rely on the pollutants (and their respective quantities) your facility creates. This is one of the main criteria, which will define the optimum ZLD treatment system for your facility.

Firstly, what are the main business reasons you have for using ZLD?

While the main reason for the majority of ZLD implementations in India, is the requirement to comply with tougher regulations. There may be other reasons that are pertinent to take into account, such as, do you wish to use fewer chemicals, produce less waste, or simplify effluent treatment in order to lessen your reliance on finite water resources?

Your ability to direct the ZLD implementation project in the appropriate direction, depends on having this knowledge.

Secondly, what features does the entering effluent have?

It is crucial to consider the precise features of the effluent discharge, while choosing the ZLD solution. The total volume, pH, temperature, biological oxygen demand (BOD), chemical oxygen demand (COD), total suspended solids (TSS), salinity, are important factors to take into account.

Thirdly, how is the cleaned water used again in your operation?

Reusing the bulk of the treated effluent, often as much as 75% or more, depending on the site and design, is one of the key advantages of a ZLD wastewater treatment system. By extracting clean water and excluding challenging contaminants, even those with high BOD/COD/TOC levels, an osmosis membrane system can improve the quality of recycled water, making more of it available for reuse.

Fourthly, do you want to recover priceless solids, salts, and chemicals?

Your ability to recover and repurpose priceless substances,like salts, can be improved with a ZLD system. This can reduce the ZLD system's overall operating costs in part.

Fifthly, what steps can you take to lower your energy expenses?

The cost of the energy required, to power the evaporators that remove the remaining liquid from the effluent, is one of the major expenses of operating a ZLD treatment system. To reduce waste and lower disposal or evaporation/crystallization costs, in Zero or Minimal Liquid Discharge systems, you can integrate a reverse osmosis process.

Finally, what is the outcome of a pilot test or treatability study?

A research or test to ascertain how the wastewater can be handled for your process, is known as a wastewater treatability study. If the study is carried out properly, it will clearly show which contaminants are present in your wastewater stream, assisting in making sure the right treatment options are taken into account, and implemented in your wastewater treatment system.

When selecting the ideal ZLD treatment system for your plant, this stage is of utmost importance. Running an effective treatability test can assist validate the assumptions you've made about potential contaminations, and methods to remove them, once you've identified perhaps two or three technology platforms, which fulfil your base and operational cost requirements.

Conclusion

Zero liquid discharge (ZLD) systems are receiving more attention, as effective wastewater treatment and water management solutions, for complicated industrial production, in order to meet these rising demands. The industry can recover the majority of its wastewater for recycling, thanks to ZLD, an ambitious wastewater management system.

How can Netsol Water assist?

We have an experience of over 10 years, in the water and wastewater treatment, as well as, expertise in custom-designing and producing Zero Liquid Discharge systems. In order to schedule a call with an engineer, or submit a quote request, you can also visit our website. We can guide you through the process of coming up with the best solution, and a reasonable price for your ZLD treatment system requirements.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.