Overview

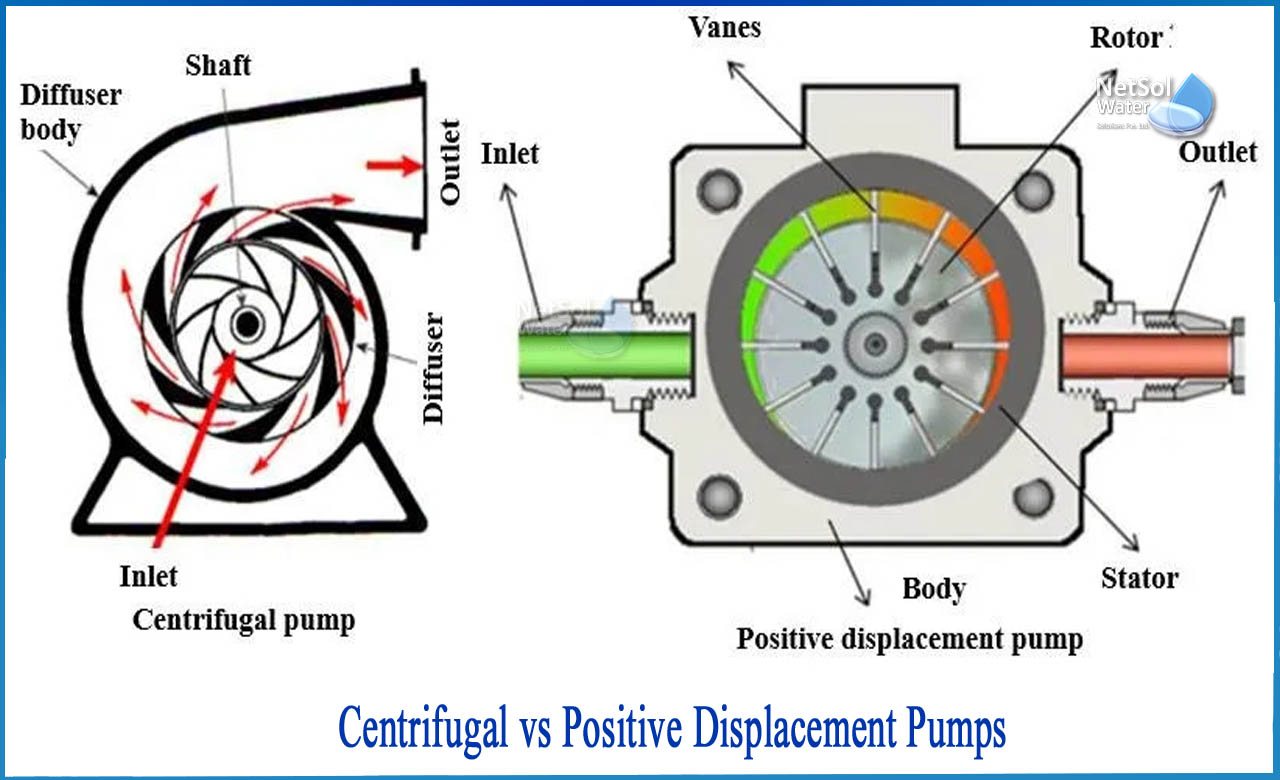

Pumps used to treat wastewater are classified as either centrifugal or positive displacement. Both of these types of pumps have advantages and disadvantages, making it difficult to determine which one is best for your needs.

To make the best decision, it's critical to understand the differences between centrifugal and positive displacement pumps!

Centrifugal pumps

They use a spinning impeller to transfer kinetic energy from the motor to the liquid. As the impeller rotates, fluid is drawn in, increasing velocity, and moving the fluid to the discharge point. Non-positive displacement pumps include centrifugal pumps.

Positive displacement pumps

The operation involves trapping a fixed volume of fluid, usually in a cavity, and then forcing that trapped fluid into the discharge pipe.

What is difference between Centrifugal and Positive Displacement pumps?

To understand how these pumps differ, you must first understand how each pump works!

Positive displacement pumps draws a fixed volume of liquid into the pump via the suction valve, trapping it within the pump's cavity, and forcing it out via the outlet valve. Depending on the type of positive displacement pump, the liquid is forced out through the outlet valve in a different way. A positive displacement pump, for example, is designed to force liquid out by moving a piston up and down through the pump's body.

Other positive displacement pump models, such as screw pumps and gear pumps, do not have moving components. These pumps, on the other hand, use rotating components to force liquid from one side of the pump to the other.

Centrifugal pumps are well-known for their straightforward design. The impeller, a rotating device that moves fluid through the pump, is the most important component of a centrifugal pump. The impeller rotates to draw fluid into the pump, then transfers kinetic energy from the motor to the fluid as it moves through the pump.

How does pressure affects flow rate?

The ability of a positive displacement pump to produce a consistent flow rate is one of its primary advantages. When the pressure changes, the flow rate of a positive displacement pump remains constant.

This is not the case with centrifugal pumps, which are designed to respond to pressure changes. A centrifugal pump's efficiency peaks at a certain level of pressure. When the pressure is not at this level, the efficiency of the pump decreases. As a result, changes in pressure will affect the flow rate of centrifugal pumps.

The Shearing of Liquids

The centrifugal pump design is less than ideal for handling shear sensitive mediums due to the high speed of the spinning impeller. Positive displacement pumps are not designed with high-speed components, so they do not apply a lot of shear to mediums. As a result, when working with shear-sensitive mediums, it is best to use a positive displacement pump.

Conclusion

When selecting a pump, it is critical to consider the operating conditions of the pump.

To handle a large volume of low viscosity fluid in a low pressure environment, a centrifugal pump is recommended. The centrifugal pump is most effective when transporting water, but it can also transport low viscosity chemicals and fuels.

Centrifugal pumps, due to their simple design, can be made of a variety of materials, including plastic, stainless steel, and cast iron. This makes it more adaptable because its design can be modified to meet your specific requirements. This type of pump is also very compact, making it an excellent choice when there is limited space for a pump.

Positive displacement pumps are commonly used to transport oil, sewage, and slurry. Positive displacement pumps are also ideal for pumping solid-containing fluids. Positive displacement pumps are used whenever the conditions for centrifugal pumps are not ideal. Changes in pressure, for example, have a significant impact on the flow rate of a centrifugal pump. When there will be pressure changes, it is best to use a positive displacement pump because this will not affect the flow rate of this type of pump.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.