Brief study about the design and operation of water softeners

HOW ARE WATER SOFTENERS DESIGNED?

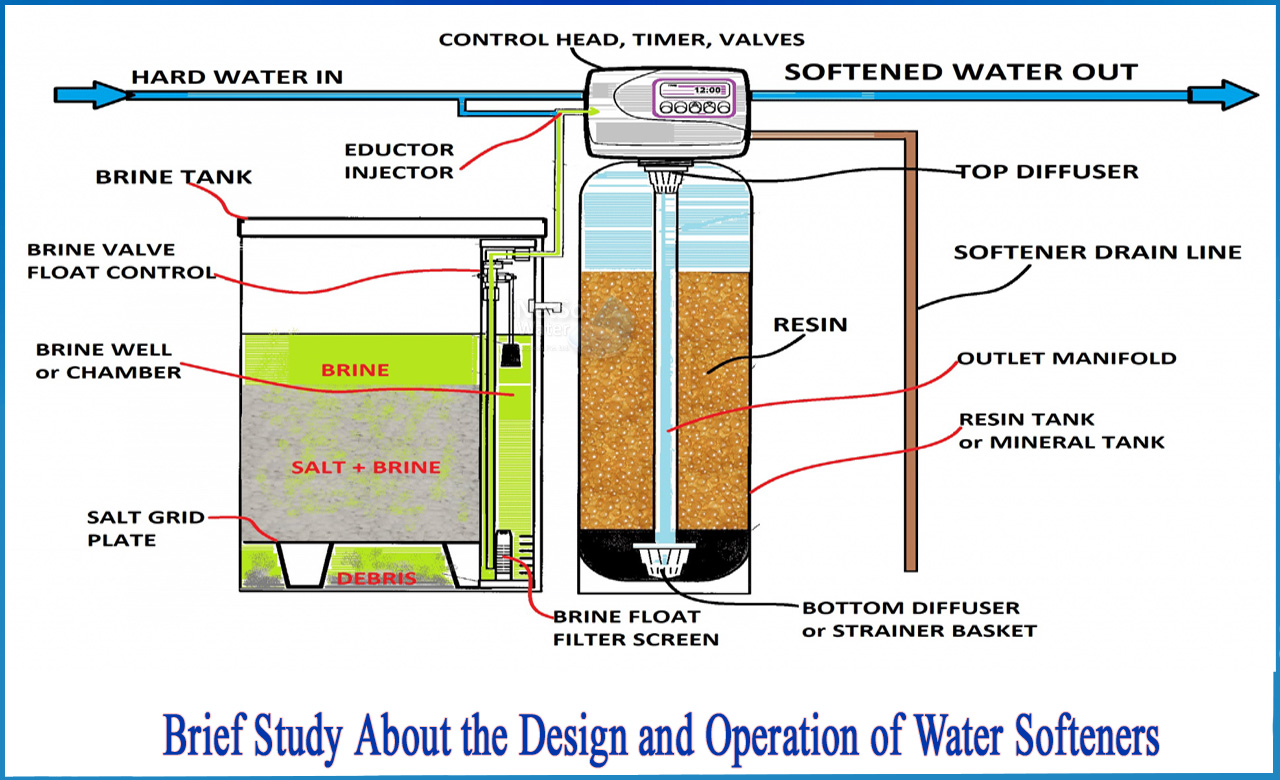

The primary components of water softener are:

1-Control valve or digital controller

· The far more important part of a Softener

· Controls the flow of water during regeneration cycles.

· Installed on top of the Resin Tank.

· Typically, Timed or Metered Regeneration is available.

2-Brine salt tank

· The brine tank is used to generate solution for cation resin regeneration.

· The salt in the brine tank is used by the softener system.

· Salt has been specially formulated for the ion exchange process as well as to keep the resin clean. The salt reacts with water to form a brine solution, which is then flushed through the resin during regeneration.

3-Resin tank

· This is the most visible component of a Softener, with the Control Valve mounted on top.

· The tank of a water softener holds the resin that is used to remove dissolved solids (Ca and Mg) from water.

· The tank is filled with thousands of tiny beads known as "resin beads."

4-Cation resin

· Cation resin in the sodium state is commonly used in softeners.

· To maintain softening capacity, it must be periodically regenerated with brine solution.

· It removes hardness ions such as calcium and magnesium and replaces them with sodium ions. When the resin bed is depleted and hardness ions begin to penetrate, capacity is restored through regeneration with common salt.

OPERATIONS OF A WATER SOFTENER

Hard water is problematic because it reduces the efficiency of heat exchange systems, such as water heaters and boilers, by depositing scale on their heat transfer components. Hard water will also constrict the flow of water through pipes, causing valves to fail and causing the finish on plumbing fixtures such as faucets and sinks to deteriorate. Water softeners are used to remove dissolved minerals from an incoming water source, primarily calcium (Ca.) and magnesium (Mg). These are the minerals that are primarily responsible for the condition known as "hard water."

A water softener removes these minerals through an ion exchange process, and the softener system will typically use a brine (salt) solution to regenerate the ion exchange resin when it becomes saturated.

When comparing Water Softeners, it is critical to consider whether to use a Timed or Metered Control Valve. The Metered Valve will be more efficient and cost less to operate in almost all applications. Only after a certain amount of water has flowed through the system will a metered valve regenerate. Using a Timed Valve usually results in more frequent regeneration cycles, which consume more salt and water than the metered option.

REGENERATION CYCLES

1-Backwash:

· Backwash with a high flow rate from the bottom to the top of the resin tank

· Cycle time is approximately 10 minutes.

· Dirt rises and is removed from the system as a result.

· Bottom-to-top flow aids in "fluffing" the resin.

2-Brine rinse:

· Brine Rinse with Slow Flow from Resin Tank's Top to Bottom

· Cycle Time takes approximately 60 minutes.

· The release of Ca. and Mg that is attached to resin is caused by an increase in the salt level of Brine solution.

· Brine solution containing "freed" minerals is discharged.

3-Rinse:

· Rinse the resin tank from top to bottom with a high-flow rinsing solution.

· Cycle time is approximately 10 minutes.

· Removes any excess Sodium (salt) from the Resin Tank and "stabilises" the resin bed.

4-Brine tank refill:

· Soft Water Brine Tank Refill

· Cycle time is approximately 10 minutes.

· Soft water is routed to the brine tank, which produces brine solution for the next regeneration.