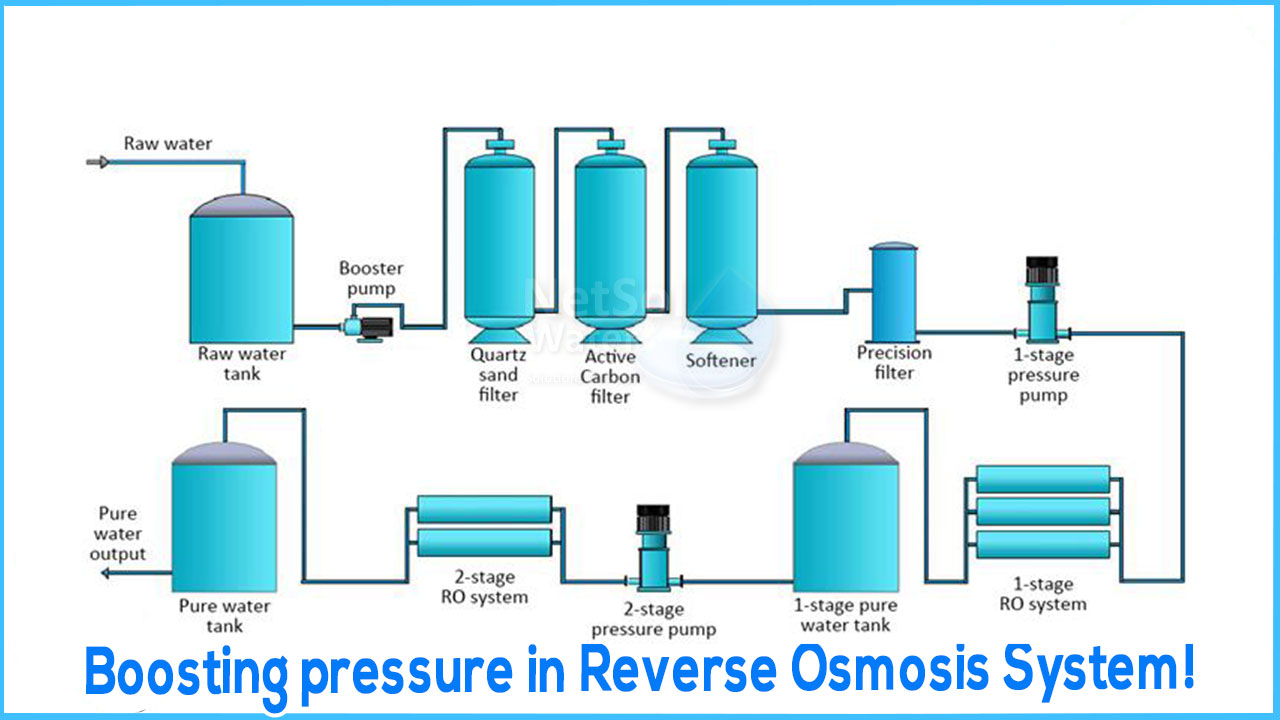

Perfect pressure for any reverse osmosis system

Most of the reverse osmosis systems and their membranes work at pressure of60psi or at higher pressure of water. They are tested to give a stable rejection rate of 97.5% at least. If the pressure of water is lower than that which is the feed line of the reverse osmosis plant, it will produce less water of lower quality when the temperature of the water is below 77-degreeFahrenheit. Normally private water systems have pressurised storage tank and pump system with 20/40 psiand 30 /50 psion switch on and off conditions respectively. In cases like this, to provide adequate rejection of specific health related contaminants in the feed water like arsenic, nitrate or others as specified by BIS or EPA, an electric pressure boosting pump must be installed.

How can I increase water pressure?

To boost water pressure in reverse osmosis system several methods are employed which are discussed below

- Use of a permeate pump to increase pressure-

Permeate pumps romantically improves the efficiency of reverse osmosis system thereby reducing wastewater rejection by 80% andduring this time, it uses the power of drain water flow from reverse osmosis system as an advantage to push the purified water into holding tank.

- Increasing pressure using electric booster pump-

In the reverse osmosis treatment plant, addition of electric booster pump increases the production rate of water, rejects more contaminants and an increase in the pipe flow rate occurs, even if the reverse osmosis membrane pressure is met by the water supply. In residential systems the diaphragm booster pumps are used which increases the feed pressure to 75-100psi.

Install the pump in reverse osmosis feed line such that the pressure may increase using the following guidelines:

-There should always be a sediment filter which acts as a protector of pump against particulate matter in water.It is advised that the pump should be installed between sediment filter and carbon filter because pumps installedafter the carbon filter will restrict the water flow and start the pump.

-Tanks which should be located nearby to the reverse osmosis tank as possible to avoid cycling of pump.

-All the tubing should be installed correctly so that they may not become cause of failure of system.

-Leaks can be developed if boosted pressure is too high around 100 psi. Reverse osmosis plant and pipeline of house can develop leaks. Pressure can be lowered through adjustment screw on pump.

- Using a solenoid-

Commercial reverse osmosis plants generally found in the market and high quality residential reverse osmosis plants use solenoid in internal plumbing to increase pressure of the plant. Two switches are used to control pressure in the booster pump. The low-pressure switch is located at inlet which makes sure that the pump is not running at dry condition. The high-pressure switch whichactivates act 40-80psi is used to automatically cut power the pump when the storage tank has reached its full capacity. The solenoid ball also stops feed water to the membrane while the pump is switched off preventing water wastage.