What are the Basic Concepts of ZLD Systems?

A wastewater treatment procedure, known as Zero Liquid Discharge (ZLD), makes sure that no industrial wastewater is released into the environment, along with any liquid waste. Our environment is not negatively impacted by this treatment option at all. This procedure involves controlling and treating wastewater through recycling, recovery, and reuse, in the industrial sector. As a result, the ZLD process is a closed-curve cycle without discharge.

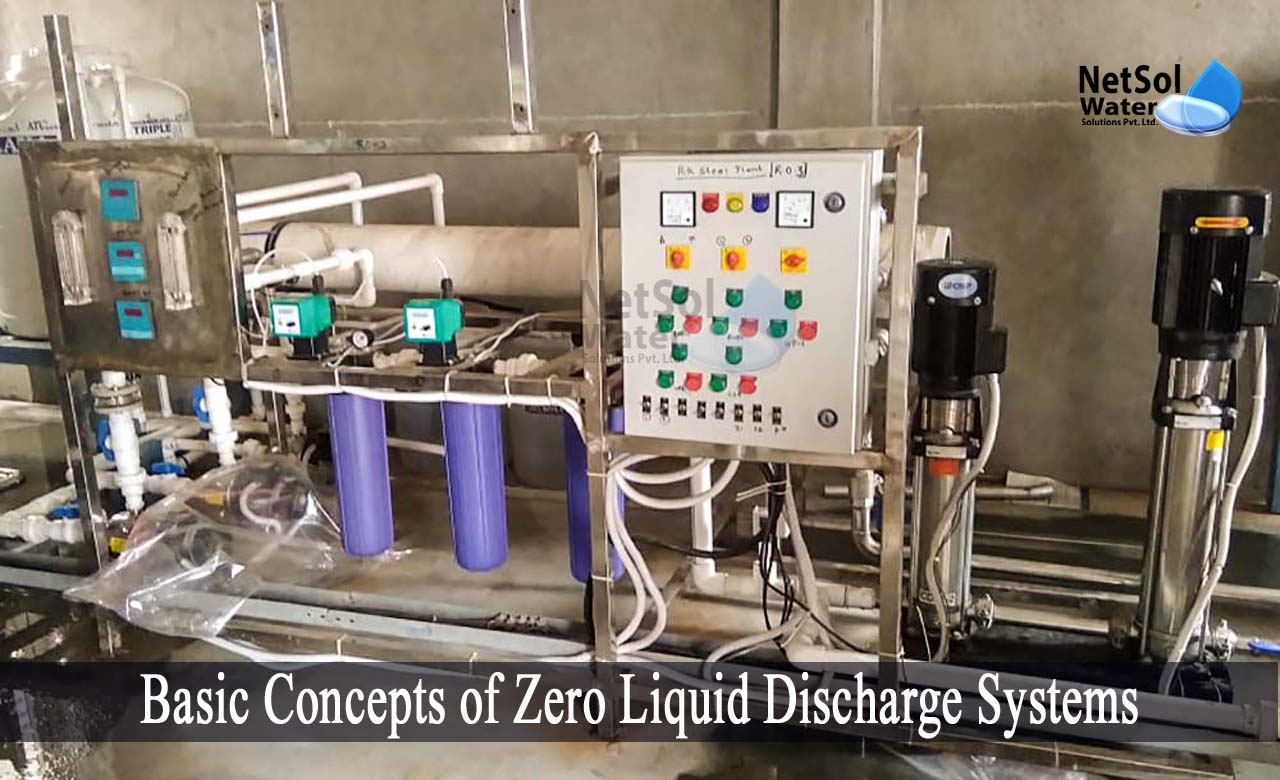

Basic Concepts of Zero Liquid Discharge (ZLD) Plant

Reverse osmosis, ultrafiltration, evaporation or vaporization, and fractional continuous deionization, are all components of the improved wastewater treatment method, known as Zero Liquid Discharge Plant. The wastewater is managed by recycling, followed by restoration, and reuse for commercial uses.

The ZLD Systems are inspired by a number of things, including:

The approach is successful when the effluent is treated using a variety of techniques, including membrane-based, and a few evaporation-based systems, as well as water restoration and recycling.

Several significant factors include:

· Environmental regulations

· Balancing and restoration

· Water Scarcity

Several benefits provided by Zero Liquid Discharge Systems

The Zero Liquid Discharge system has the following advantages:

* Recycling which prevents wastewater discharge.

* This approach enhances environmental performance, and the regulatory risk profile for upcoming permitting.

* Water and salt recovery helps to keep ZLD's operating costs down.

* The ZLD method supports the sustainability of the business, and the environment as a whole.

* Water is used far less in the textile industry, which means that it is still available for other uses like irrigation (agricultural), and household utilities.

*The cement business may use the sludge appropriately.

* It makes it possible to recover better surroundings.

Important elements necessary for a ZLD System:

Three add?itives in particular may be absolutely necessary for a structured ZLD process:

1: Pre-treatment, i.e., Biological & physico-chemical.

2: Membrane methods, like Reverse osmosis.

3: A crystallizer and an evaporator (thermal processes).

Conclusion

Freshwater is becoming an increasingly important resource nowadays, and unless the water is treated, commercial practices threaten its availability on multiple fronts. Living far away from those types of settings, ZLD could be very important to utilize. Many commercial methods demand water, which reduces the availability of water for the environment, or other strategies, or alternatively contaminates and releases water, which harms the neighbouring environment. Resource recovery from wastewater using this Zero Liquid Discharge (ZLD) technology is also very beneficial.

Zero Liquid Discharge Plant Services in India

To meet all of your demands, Netsol Water, based in Greater Noida, India, provides complete thermal and non-thermal Zero Liquid Discharge services, and manages difficult-to-treat wastewaters from manufacturing to installation. Our ZLD Plant is simple to use and is created using cutting-edge equipment and technology, to produce zero liquid waste.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.