Overview

For treating industrial wastewater, anaerobic treatment is a proven and energy-efficient technology. In an oxygen-free environment, it uses anaerobic bacteria (biomass) to transform organic pollutants or COD (chemical oxygen demand) into biogas.

Anaerobic micro-organisms (specific to oxygen-free conditions) are selected for their ability to degrade organic matter present in industrial effluents, converting organic pollutants into biogas (methane + carbon dioxide) and a small amount of bio-solids. The biogas, which is high in energy, can then be utilized as boiler feed or combined heat and power (CHP) to generate ‘green’ electricity and heat.

Compared to aerobic treatment, anaerobic treatment has various advantages:

-Low energy use

-Small reactor surface area

-Lower chemical usage

-Reduced sludge-handling costs

This article will provide an approachable introduction to anaerobic treatment and attached & non-attached biomass!

What is anaerobic wastewater treatment?

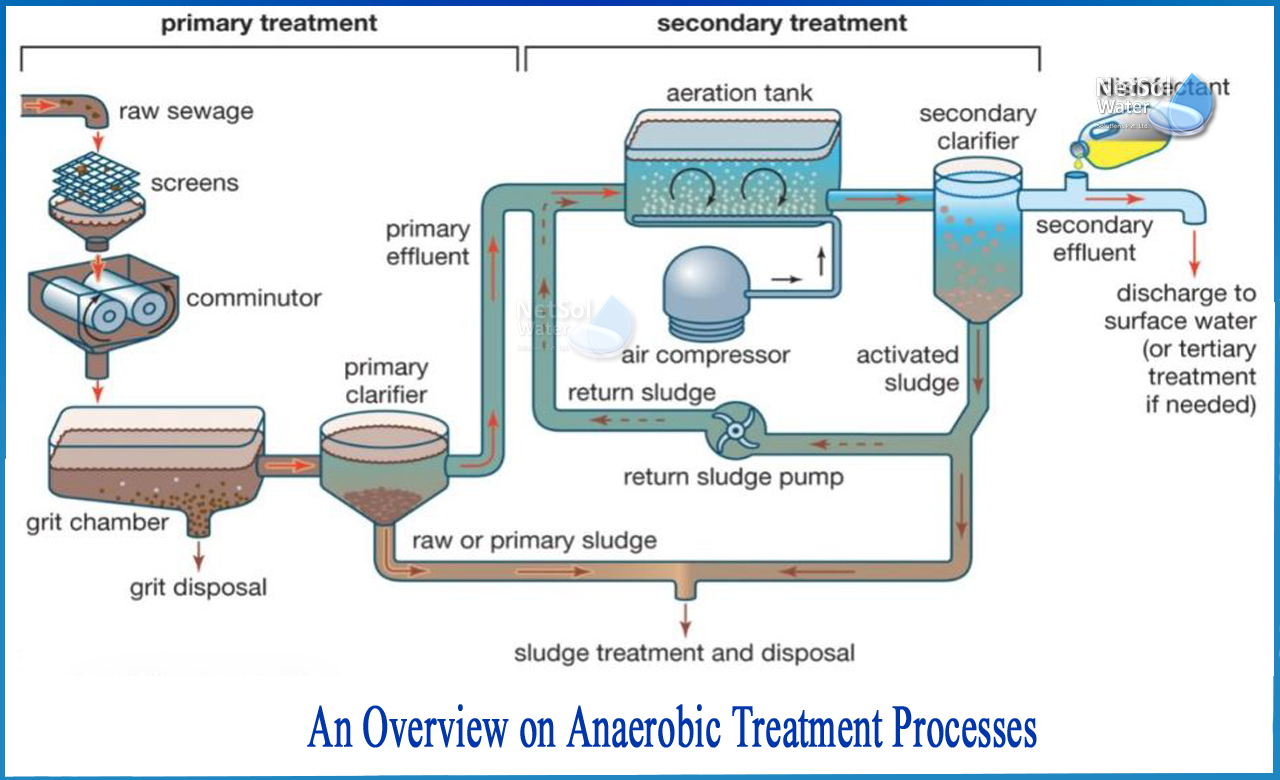

Anaerobic wastewater treatment is a biological process in which organic pollutants are degraded by microorganisms in the absence of oxygen. Wastewater enters a bioreactor receptacle in a typical anaerobic treatment cycle. The bioreactor is filled with sludge, a thick, semi-solid substance made up of anaerobic bacteria and other microorganisms. These anaerobic bacteria, sometimes known as "anaerobes," digest the biodegradable materials in the wastewater, resulting in an effluent with decreased BOD, COD, and/or TSS, as well as biogas byproducts.

Applications of Anaerobic digestion

Anaerobic wastewater treatment is used to treat a wide range of industrial effluent streams, including municipal sewage sludge and wastewater, as well as agricultural, food and beverage, dairy, pulp and paper, and textile effluent streams.

Anaerobic technologies are generally used before aerobic treatment for streams with high amounts of organic material (measured as high BOD, COD, or TSS). Anaerobic treatment is also suitable for treating warm industrial wastewater and is utilized for specialized applications such as the treatment of waste streams containing inorganics or chlorinated organics.

How does anaerobic wastewater treatment work?

Anaerobic wastewater treatment is a type of biological treatment where anaerobic micro-organisms are used to break down and remove organic contaminants from wastewater. While anaerobic treatment systems come in a range of shapes and sizes, they invariably involve a bioreactor or repository that can sustain the oxygen-free atmosphere required for anaerobic digestion.

The anaerobic wastewater treatment process is divided into two stages:

Acidification and methane generation, with both processes operating in dynamic equilibrium.

Anaerobic digesters have been used for decades to stabilize sewage sludge, their efficient and cost-effective usage for the treatment of liquid wastes is a relatively new phenomena, owing to the development of innovative reactor designs. These ideas have resulted in the development of a number of reactors that can hold a significantly higher biomass concentration than standard digesters. This is made possible by making sludge retention independent of influent retention time.

The following are the technological options that enable for this requirement of independent sludge retention time:

a) Biomass attachment to media (filters, fluidized systems, and RBC designs);

b) Biomass non-attachment as a suspended growth process (sludge blanket reactors and contact process with sludge recycling).

Evaluation of Attached bio-mass filters and non-attached bio-mass filters-

Because generalizations are rarely useful in practice, evaluating the advantages and disadvantages of one system in relation to other notions is difficult. Purification rates, loading rates, investment costs, energy balance, space needs, operational expenses, and specific long-term experience with certain wastewaters are all essential considerations, although they will be valued differently depending on the industry.

In attached bio-mass,microbial cultures are freely suspended in the reactors. Microorganisms are suspended in wastewater, either as a single cell or in aggregates.

There are two stages to the non-attached biomass process:

The contact phase:The raw waste is intimately mixed with a previously created and available anaerobic sludge culture in the reactor during the contact phase; and

The separation phase: The active sludge particles are removed from the treated liquor and recycled to the contact unit during the separation phase. Raw wastewater is combined with recycled sludge solids and digested in a digestion chamber in this procedure.

The mixture is separated in a clarifier (or vacuum flotation machine) after digestion, with the supernatant released as effluent. Sludge that has settled is then recycled to seed new garbage. The sludge retention in an anaerobic reactor determines the loading rates allowable in an anaerobic waste treatment process. The maintenance of a high Sludge Retention Time (SRT) has been a key issue in the process's practical use, particularly for waste with a COD of less than 3000 mg/L. Clearly, a waste treatment process for low-strength wastes is cost-effective if a significant volume of waste can be pushed through the system in a short period of time.

Processes that allow the biomass retention period to be regulated independently of the wastewater flow rate are required for this purpose.

How can Netsol help?

Netsol Water have expertise in wide range of water and wastewater treatment technologies. We can customize wastewater treatment plants that will cater to all your needs and at the same time effectively treat different types of wastewater. We are dedicated to provide hands on service, expert counselling and training to our valuable customers.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.