What is Corrosion in Wastewater Treatment Plant?

Corrosion is the natural deterioration of metals. External elements such as humidity, temperature, and corrosive gases, primarily active sulphur compounds, sulphide oxides, and nitrogen oxides, influence this process (H2S, SO2, SO3, and NOx).

These factors are present in pumping stations and sewage treatment facilities, even in very low concentrations (parts per billion), and are the cause of technical and operational problems owing to electrical component degradation.

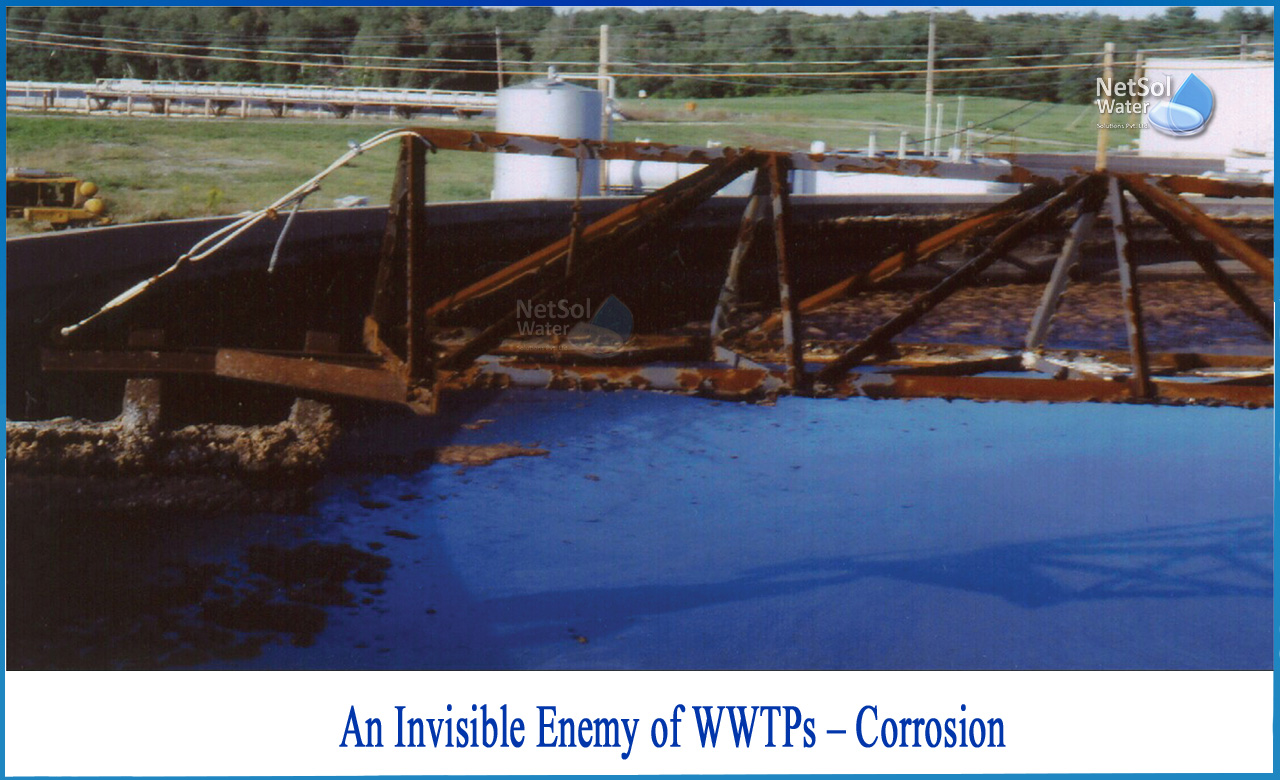

Corrosion can limit the life of parts of the wastewater treatment plant and distribution systems, as well as water storage tanks. Wastewater treatment systems face an even stronger battle against corrosion due to the harsh climate and the presence of hydrogen sulphide gas. When we think of corrosion, we usually think of steel, but concrete can also corrode when exposed to harsh circumstances. To prevent corrosion, the steel reinforcing bars that provide concrete its tensile strength must be covered.

Knowing the enemy of WWTP, “corrosion”, it is essential for preserving the steel and concrete of water and wastewater assets.

Bacteria – a factor of corrosion

In terms of corrosion, the bacteria that create sulphur compounds as a result of their metabolic processes are the most important. This action could produce acidic chemicals that are harmful to concrete, steel, and cast iron. Some bacteria also oxidise iron to iron ions, which significantly alters the immediate environment.

Sulphur-oxidizing bacteria (SOB) colonise damp surfaces with a pH more than 9.5 and oxygen. Aerobic SOB is particularly active in the facility's loose layers, which are nutrient-rich. These kinds of locations can be found just above the water line.

SOB metabolise H2S and other sulphides to sulphuric acid using dissolved oxygen (H2SO4). SOB is a term used to describe a group of Thiobacillus, which is an acid-forming bacterium that is also a member of the Thiobacillus genus. In sewage treatment plants, sulphuric acid is produced.

Preventing corrosion

The anode, cathode, and metallic path (ACM) are all found in every piece of steel, while the electrolyte is made up of water, wastewater, and even air moisture. Placing a barrier between the steel or concrete and the electrolyte is the most straightforward technique to avoid corrosion i.e., paints, coatings and linings.

Water and wastewater structures should be constructed to be easy to paint and repaint to prevent corrosion. Skip welds, edges and angles, overlapping plates and fissures, inaccessible locations, and water traps must all be reduced or eliminated.

Other methods of corrosion prevention exist.

To avoid forming a corrosion cell, two dissimilar metal surfaces, such as carbon steel and stainless steel, must be isolated (i.e., painted or installed with a gasket). Corrosion cells can be created by using incompatible nuts and bolts.

In extremely hostile situations, high-tech plastics, fibre-reinforced plastics, or expensive corrosion-resistant metals such as stainless steel may be required instead of coated steel and concrete. After gaining a better understanding of corrosion, time and resources must be dedicated to prevent corrosion from reducing the useful life of water and wastewater assets.

Conclusion

In numerous situations, microbiological corrosion has caused concrete structures to deteriorate to the point where repairs are required after four years, followed by ultimate destruction after six years. It is required to apply coatings that create a barrier and are resistant to microbiological attacks in order to protect concrete from microbiological attacks.

Biogenic inorganic acids (sulphur, nitrate) and organic acids have an effect, the most important characteristics of such coatings. Acid resistance, strong adherence to steel and concrete, and lack of permeability are all characteristics that should be present. Resistance to the effects of salts is also important.

In wastewater treatment plants, corrosion is so common where there is water and air both in contact. Netsol provides you with the best methods for providing best possible ways to prevent corrosion.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.