What is aeration?

Aeration, or oxygen transfer, is an old technique that still plays a vital role in our environment by increasing the dissolved oxygen concentration in water.

Atmospheric re-aeration is a natural process that transfers oxygen from the atmosphere into streams and lakes. This restores the oxygen depleted during the biodegradation process and improves water quality.

Meta-limnetic and hypo-limnetic aeration can both be used to boost oxygen levels in deep lakes and reservoirs. Aeration has long been used in industrialized nations to reduce algae blooms in eutrophic lakes.

Is aeration a critical parameter?

Aeration is critical in the aquaculture sector for shrimp and catfish cultivation, as well as fermentation for a variety of businesses.Aeration must be utilized in hydropower facilities to prevent cavitation in the spillway and meet the discharge limit for dissolved oxygen.

Aeration is also the most important procedure in the proper operation of an aerobic biological wastewater treatment system. The biological therapy procedure will not work unless dissolved oxygen is accessible where and when the bacterial system wants it.

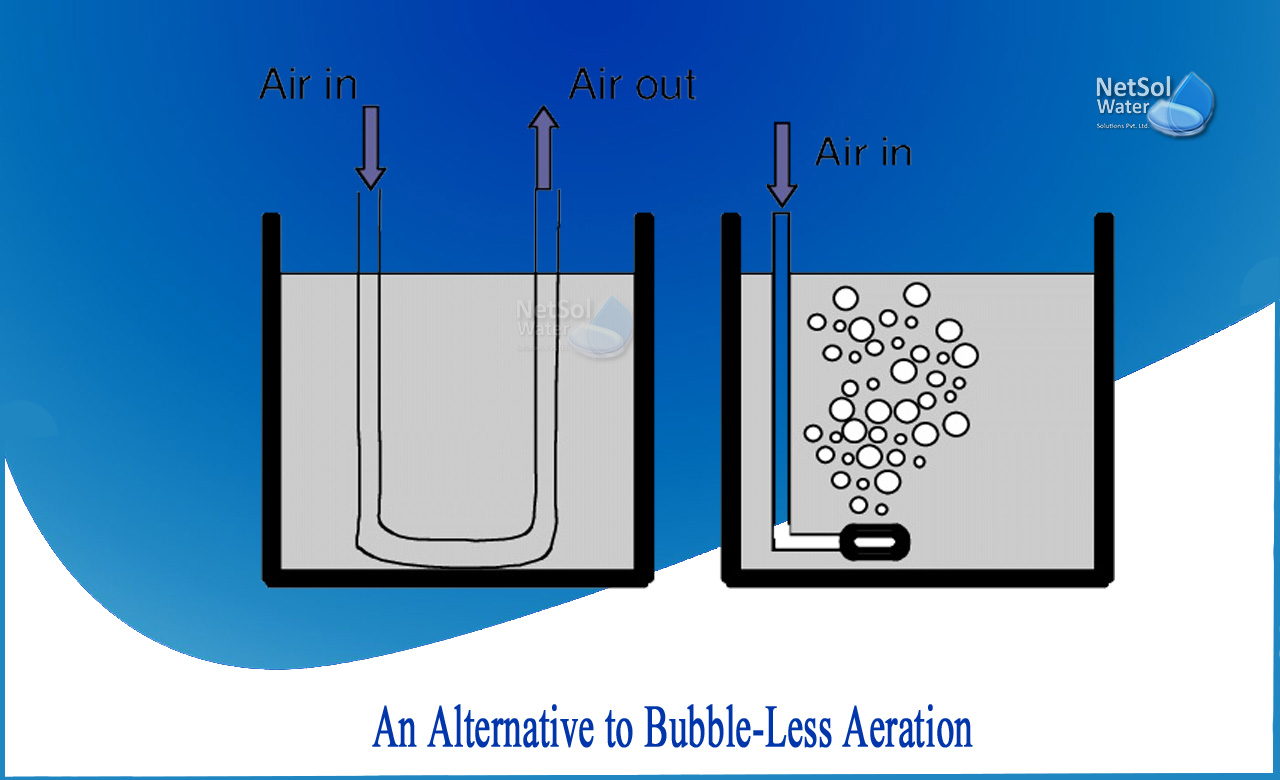

How to Develop a Bubble-Less Aeration Alternative?

The majority of energy is consumed in the secondary or biological stage of typical activated sludge wastewater treatment facilities. It considerably eclipses the operational expenses of pumps, mixers, chemical addition, lights, and heating, among other things. The oxygen required for bacteria in this stage is often given in the form of atmospheric air, via mechanical equipment, and against a hydrostatic pressure caused by four to six meters of water depth. To guarantee that all bacteria receive adequate oxygen, rotating blade mixers, jets, and/or huge blowers are required to drive air through this pressure (head).

Engineers and manufacturers have worked hard in recent years to improve oxygen transfer efficiency. Given that a big number of little bubbles have a larger surface area than a small number of large bubbles, the hunt for aeration products that produce smaller and smaller bubbles has been continuing.Small classic discs and tubes are losing way to huge panels as the number of holes and surface area of diffusers increases. These offer tiny bubbles, excellent distribution, and cheap energy costs.

The innovative idea with advantages

1: The idea of creating the tiniest bubble possible with an indefinitely small surface area sounds sensible, and it is reasonable to expect that the oxygen transfer rate will grow. Other treatment plant characteristics, however, must be evaluated. There are no two wastewater treatment facilities alike; each has unique fluid, location, and mechanical properties. The majority comprise solids, and all contain living materials.

2: Smaller membrane holes may foul faster than larger membrane perforations, therefore a device that generates tiny bubbles while new may not function properly after some time in use.The mere presence of a hole invites trouble. Maintenance may be expensive.

3: Blower back pressures will most likely be greater in systems with smaller membrane perforations, while less air may be required because the system has the ability to transport oxygen more effectively than a bigger bubble system. Designers should account for larger motor blowers and higher power consumption owing to increasing back pressures.

4: Then there's the effect of having a really efficient fine bubble system, which designers frequently miss, and many owners are just unaware of.If their system is built to be very efficient and requires less air, there may not be enough air in the biological zone to keep the food and bacteria suspended.

An activated sludge system works best when the bacteria are maintained suspended and have access to lots of food and air. Solids settling out in a typical activated sludge system can be harmful.

Conclusion

We, Netsol Water, being one of the most reputable manufacturers of waste water treatment plants in India, can deliver the novel bubble aeration process by tailoring to the customer's demands.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.