Discuss about Municipal Wastewater treatment systems?

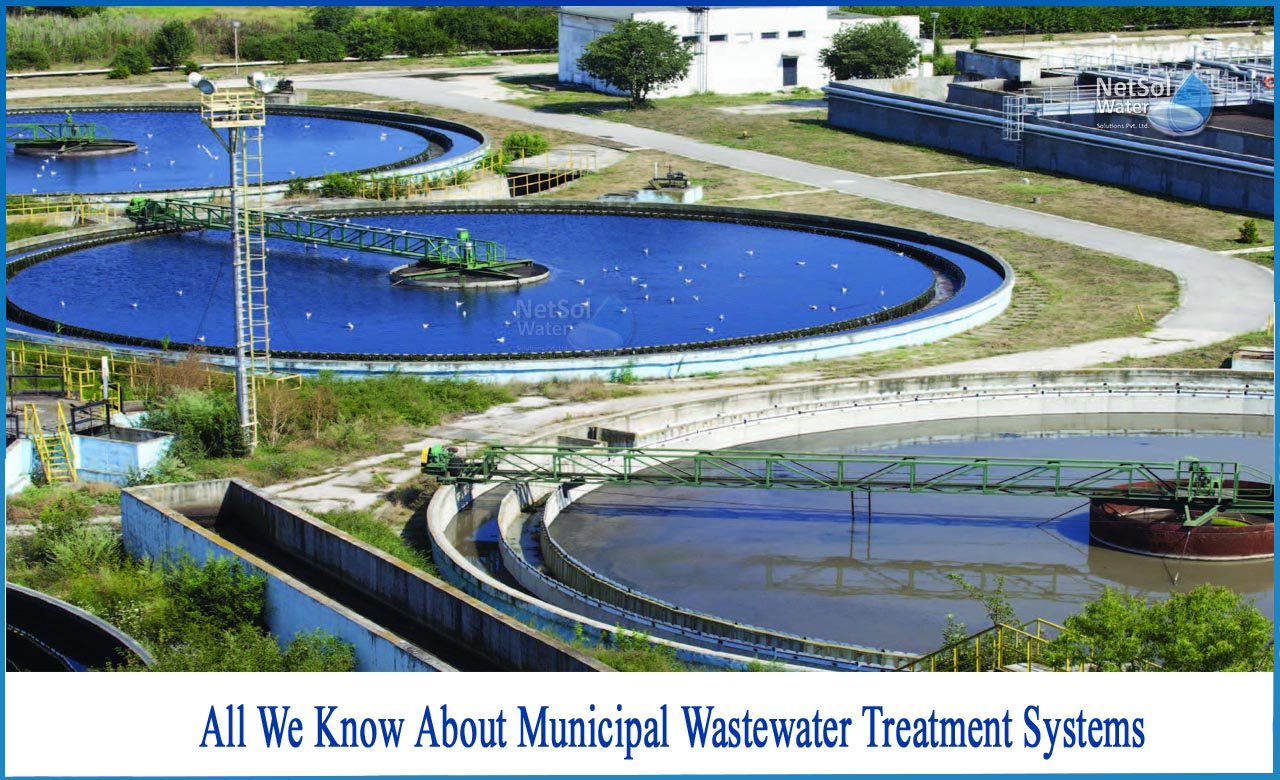

Municipal wastewater treatment plants clean and disinfect wastewater collected from sewers and private septic systems. When the effluent fulfils all of the relevant quality measurement requirements, it is discharged into bodies of water or restored to the public drinking supply.

The Operation of Wastewater Treatment Plants

The essential principles of wastewater treatment are as follows:

Wastewater enters, foreign items and sediments are removed, the residual water is aerated and purified, microbes digest any minute particles of waste/food, and chemical additions kill off anything remains. The final phase is UV, which aids in the removal of chemicals that have been introduced.

We have integrated systems that collect sewage and stormwater and transport it to a wastewater treatment facility for treatment. Separate units are more prevalent. All modern wastewater treatment systems are designed to separate wastewater from rainwater. Stormwater is recycled into streams or rivers, whereas wastewater is processed at a treatment facility.

Steps in Primary Wastewater Treatment

When wastewater from sewers enters the plant, it may need to be pumped from a lower elevation to a higher elevation for first treatment. The sewage is delivered to the settling tanks using open or enclosed screw pumps. Wastewater will be filtered through screens before being routed through a grit chamber to remove impurities such as plastic applicators, plastic wrappers, and grit such as coffee grounds.

Grit removal is critical for extending the life of your equipment. Sand and grit may wear out components over time. By removing grit, you may improve the life of your pumps and valves. You also avoid obstructions. As the treatment process proceeds, this aids in aeration and digestion.

Pumps must be able to manage variable flow rates as wastewater is pushed into the next region of the treatment plant. A sewer may appear to have higher flow rates in the morning as people prepare to leave for school and work, and again in the evening as people return home for the day. Flow rates will slow down when individuals are asleep.

Secondary Treatment

The sludge sinks to the bottom of the primary clarifier. Liquids (primary effluent) go to the aeration tank, where they are mixed up and oxygenated. Sludge is pumped out and sent to a treatment facility where it will be processed and disposed of. It does not remove all of the sludge particles. The water in aeration tanks is mixed to provide the oxygen that bacteria requires. The oxygen keeps microorganisms alive, and they feed on the organic molecules that remain.

Some wastewater treatment plants utilize filters to remove contaminants before advancing to a secondary clarifier. Another alternative that comes before secondary clarifier is activated sludge treatment. The sludge settles again, and some is pumped out, while some returns to the aeration tank for a second cycle, and clean water flows on to tertiary treatment.

Tertiary Treatment

Biological therapy solutions may be used in tertiary treatment. To assist destroy any leftover impurities, disinfectants are applied to the wastewater. Many plants still employ chlorine to guarantee microorganisms are destroyed. The remaining wastewater is then subjected to UV light to help eliminate the chlorine that is frequently used to help disinfect the water. Wastewater is tested to ensure that it fulfils Government requirements.

Conclusion

Each municipal wastewater district must work hard to ensure that wastewater fulfils regulatory standards while being inexpensive to the water district's members. It can become an issue if taxpayers are unable to cover the expense. You also don't want a plant that can't keep up with expanding demand as additional residences and businesses are developed in the area. You'll perform well with a properly-designed wastewater treatment facility that takes into account expansion, energy efficiency, and efficacy.

Netsol Water is Greater Noida-based leading water & wastewater treatment plant manufacturer. We are industry's most demanding company based on client review and work quality. We are known as best commercial RO plant manufacturers, industrial RO plant manufacturer, sewage treatment plant manufacturer, Water Softener Plant Manufacturers and effluent treatment plant manufacturers. Apart from this 24x7 customer support is our USP. Call on +91-9650608473, or write us at enquiry@netsolwater.com for any support, inquiry or product-purchase related query.